Understanding Lithium Battery Cell Purchasing from China: Navigating Quality and Shipping Challenges

The process of purchasing from China lithium battery cells, particularly for do-it-yourself (DIY) projects, is fraught with complexities and pitfalls, largely stemming from issues of quality and shipping. As a specialist in the field with extensive experience, I aim to experienced on these challenges, providing insights that stem from my personal journey in navigating this treacherous terrain.

The Allure and Risks of Using Alibaba

Many importers continue to be drawn to platforms like Alibaba due to apparent cost savings and convenience. However, a significant risk lurks beneath the surface: approximately 90% of importers end up with subpar, or “B grade,” cells. This pervasive issue is largely attributable to the shipping practices and the inability to visually distinguish between A and B grade cells.

Why Most Cells Are B Grade

The core of the problem lies in the shipping practices employed by many Alibaba vendors. These sellers often resort to “black market shipping,” where containers filled with dangerous goods (like lithium batteries) are not properly declared. This involves using what is known in Chinese as “special line” shipping, which typically involves bribes to customs officials in both China and Australia.

This unorthodox approach allows sellers to dramatically reduce shipping costs—sometimes by half compared to reputable companies like EVE Energy, which adhere strictly to international shipping regulations for dangerous goods. EVE Energy, being a billion-dollar enterprise, cannot risk the legal and ethical implications of concealing dangerous goods in regular shipments.

The Difference Between A and B Grade Cells

From a technical perspective, A and B grade cells may appear identical, but their performance and reliability diverge significantly. EVE Energy, for instance, implements rigorous testing procedures during their 3-4 week manufacturing process. This includes specialized charging processes, capacity checks, and voltage tests, which classify cells into categories like A+, A, B, and B- grades. Up to 40% of cells are downgraded to a lower grade due to identified defects during these tests.

Our Approach: Ensuring Quality and Compliance

Given the complexities of legally and safely importing lithium cells, I have taken the route of organizing my own shipping and securing necessary certifications for transporting dangerous goods. This approach, while time-consuming and complex, ensures that I provide only A+ grade cells, unlike the prevalent B grade cells that flood the Australian market through less scrupulous importers.

The Misrepresentation by Alibaba Sellers

A common tactic among Alibaba sellers is falsely representing B grade cells as A+ grade. This misrepresentation is facilitated by the structure of the supply chain, where cells are warehoused en masse and drop-shipped by vendors who often operate merely as call centers. The consequence is a market flooded with inferior cells sold under the guise of top-tier quality.

Conclusion: Navigating the Lithium Cell Landscape

The challenges of purchasing lithium battery cells from China revolve around navigating through a murky landscape riddled with deceptive practices and regulatory challenges. My expertise and commitment to quality and safety have allowed me to overcome these barriers, ensuring that I can provide genuinely high-grade lithium cells.

This situation underscores the importance of rigorous due diligence and understanding the intricate dynamics of international shipping and quality control. By sharing my experience, I aim to enlighten potential buyers and DIY enthusiasts on the pitfalls of the market and the critical importance of sourcing from reliable and ethical suppliers.

In simpler terms, buying lithium battery cells from China can be tricky. Many buyers (importers) get tempted by lower prices on platforms like Alibaba, but often end up with lower-quality, “B grade” cells due to shady shipping practices where sellers don’t declare dangerous goods properly to cut costs. This is risky and against the law.

On the other hand, reputable companies like EVE Energy follow strict shipping rules, which makes their cells more expensive but ensures they are of high quality. I’ve gone the extra mile to organize my own shipping and make sure everything is above board, which means I only provide top-quality, “A+ grade” cells.

To put it plainly, if you’re looking to buy lithium cells, it’s crucial to understand that the cheapest option might end up costing you more in the long run due to poor quality. It’s better to pay a bit more for cells that are safely and legally shipped, ensuring you get what you pay for—reliable and effective batteries.

To clearly highlight our approach: we manage our own shipping and customs processes entirely within legal frameworks. This commitment to legality and ethical practices sets us apart from many sellers around the world who often resort to shortcuts like purchasing from Alibaba to save on shipping costs.

By purchasing in bulk and overseeing every step from customs clearance to delivery, we ensure that we provide only A+ grade cells. This direct involvement allows us to maintain high standards of quality and safety, unlike many other sellers who compromise on these aspects to reduce expenses. This unique approach ensures that our customers receive the best possible product without the common risks associated with improperly handled imports.

Probably the best information we can give you is to outline the actual practices

- EVE might sell a battery for $68-78 USD A+ grade

Shipping might be $500-800 AUD for 16 cells (Its always more expensive because its legal shipping) - Alibaba sellers buy B grade cells from anywhere between 50-75% of the A+ grade price.

This means $34-56 USD - The Alibaba seller will then quote you $63-$78 for that same cell

But not only that there shipping quote to you might be $300-600. - The price is not that important, BUT! they are also making profits on the shipping because its not DG shipping. Its illegal.

- They do not declare the Batteries as DG in Australia either, so they pay $100’s of dollars less for this shipping pathway.

- This is all profit. The process has been improved over a few years. So its now down to only a couple of shipping companies who handle all of the deliveries in Australia

- In many cases, they do not pay GST either or only a tiny fraction of what should be paid.

This is our money, our countries money, that is supposed to go back into, schools and hospitals and such for the benefit of our country. No in the pockets of overseas companies who are also selling bad cells to us.

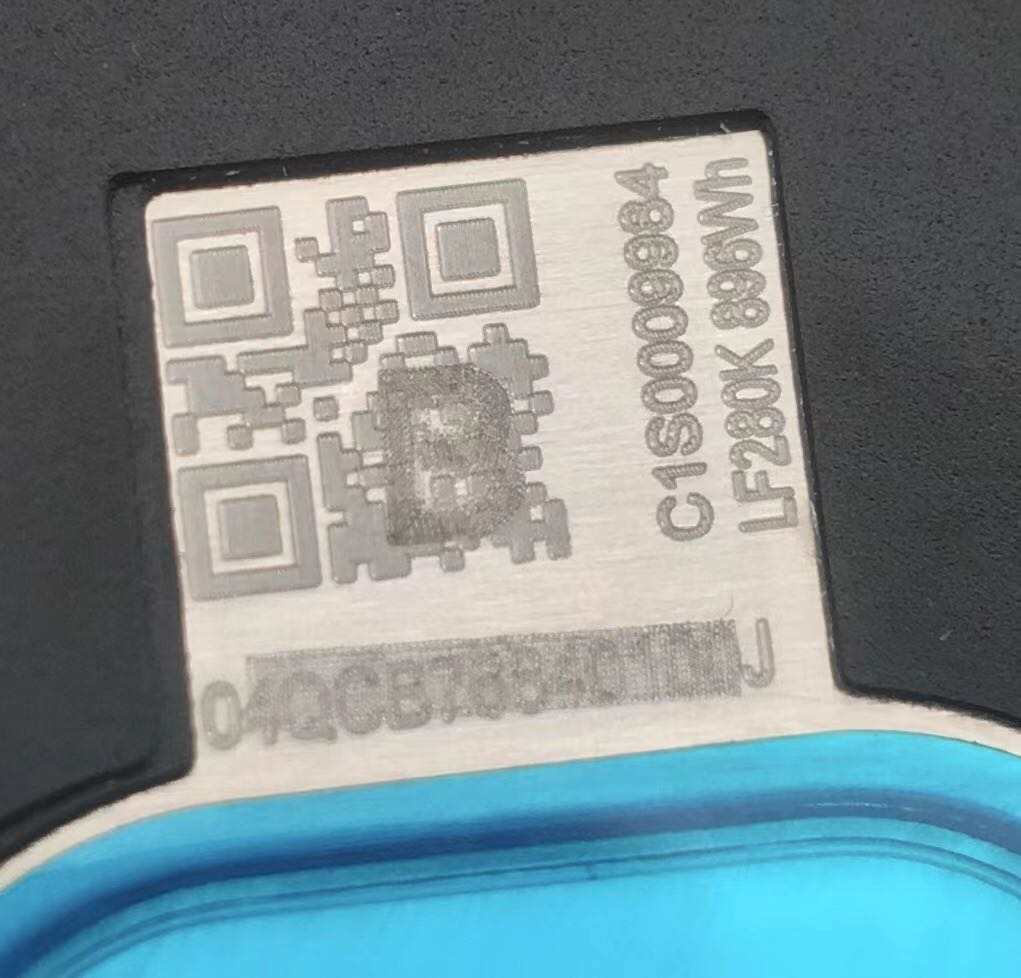

The total price is always lower through Alibaba sellers. The Alibaba seller makes $20-35 USD more per cell. This means they can put signinificant effort into replacing a QR code with valid data.

The Laser etching technique which is used to replace a QR code, machine is a very cheap investement when we are talking about replacing the QR code of thousands of cells a day. The investement into this machinery and process is now extremely profitable.

The cells are purhased in lots of thousand and hundreds of thousands. They are transported to a warehouse/ processing centre. where they are graded again and then relabelled with a new QR code. The QR code is from genuine A+ grade cells. A QR code is just letters and numbers. So this data is taken from a genuine batch of A+ grade cells. The spreadsheets from EVE A+ grade cells are used to create what appears to be A+ grade cells. This process costs about $1.50 USD per cell.