Comparing the most popular 300AH Lifepo4 cells

Comparing the EVE LF304 to the LF280, LF280K, and LF280k v3, MB30, MB31 we can analyze the key differences and similarities among these popular Lifepo4 cells.

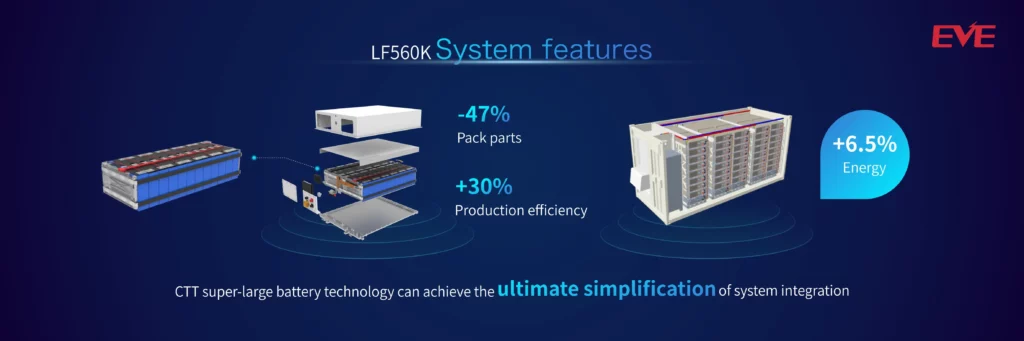

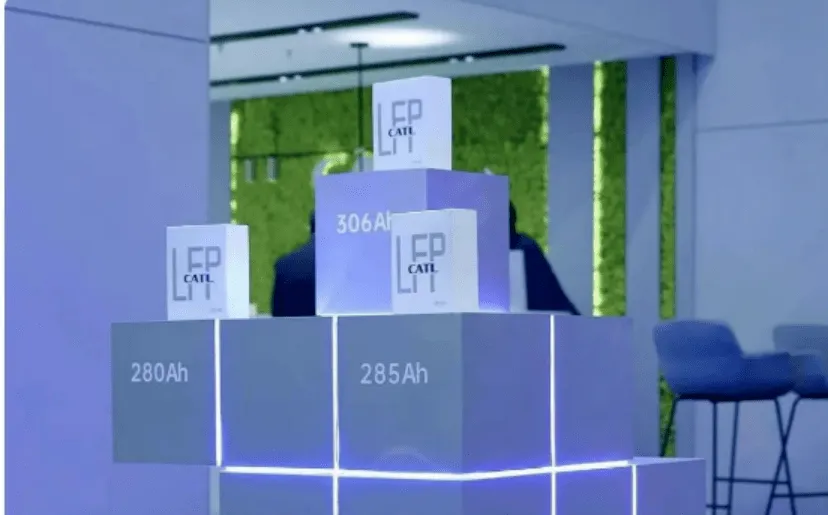

You can also find out why the next generation of MB (Mr Big) cells is better than the last, mostly due to the new stacking technique being employed by just a small number of LFP manufacturers. At this stage CATL, EVE have next generation cells, not yet freely available. But in the near future, you will be able to purchase these cells if you don’t buy them from the grey markets.

EVE LF304

The EVE LF304 has a cycle life of 4000 at 0.5C/0.5C. Giving it an estimated lifespan of up to 11 years.

The EVE LF304 is EVE’s high power cell, with thicker coatings,

Capacity: 304Ah

Nominal Voltage: 3.2V

LIFEPO4 AUSTRALIA OPINION

Cycle Life @ 1C : 2000 Cycles

Cycle Life @ 0.5C : 4000 Cycles

Claimed Cycle Life @ 1C : 4000 Cycles

Production technology – Winding

LF280

The EVE LF280 has a cycle life of 4000 cycles at 0.5C/0.5C. Giving it an estimated lifespan of up to 11 years

Capacity: 280Ah

Nominal Voltage: 3.2V

LIFEPO4 AUSTRALIA OPINION

Cycle Life @ 1C : 2000 Cycles

Cycle Life @ 0.5C : 4000 Cycles

Maximum Continuous Discharge 1C

Production technology – Winding

LF280K

The EVE LF280K has a cycle life of 6000 cycles at 0.5C/0.5C. Giving it an estimated lifespan of up to 16 years

Capacity: 280Ah

Nominal Voltage: 3.2V

LIFEPO4 AUSTRALIA OPINION

Cycle Life @ 1C : 3000 Cycles

Cycle Life @ 0.5C : 6000 Cycles

Production technology – Winding

LF280k v3

The EVE LF280K has a cycle life of 6000 cycles (A+ Grade 8000 Cycles) at 0.5C/0.5C. Giving it an estimated lifespan of up to 16 years

Capacity: 280Ah

Nominal Voltage: 3.2V

LIFEPO4 AUSTRALIA OPINION

Cycle Life @ 1C : 4000 Cycles

Cycle Life @ 0.5C : 8000 Cycles

Cycle Life: 6000 Cycles (A+ Grade 8000 Cycles)

Maximum Continuous Discharge 1C

Recommended Discharge 0.5C

Production technology – Stacking

MB30

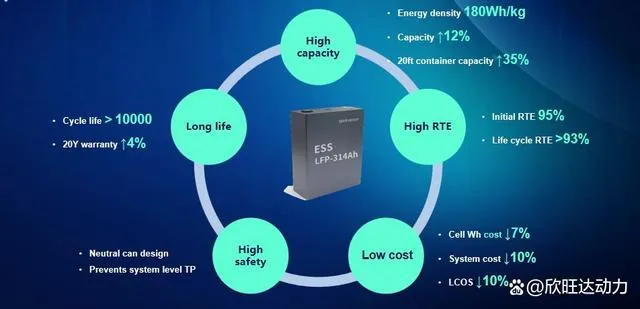

The EVE MB30 has a cycle life of 10000 cycles at 0.5C/0.5C. Giving it an estimated lifespan of up to 20-25 years

Capacity: 306Ah

Expected Real measured capacity when new 320+AH

Nominal Voltage: 3.2V

LIFEPO4 AUSTRALIA OPINION @ Thermally controlled environment

Cycle Life @ 1C : 5000 Cycles

Cycle Life @ 0.5C : 10000 Cycles

Cycle Life: 10000 Cycles

Maximum Continuous Discharge 1C

Recommended Discharge 0.5C

Production technology – Stacking

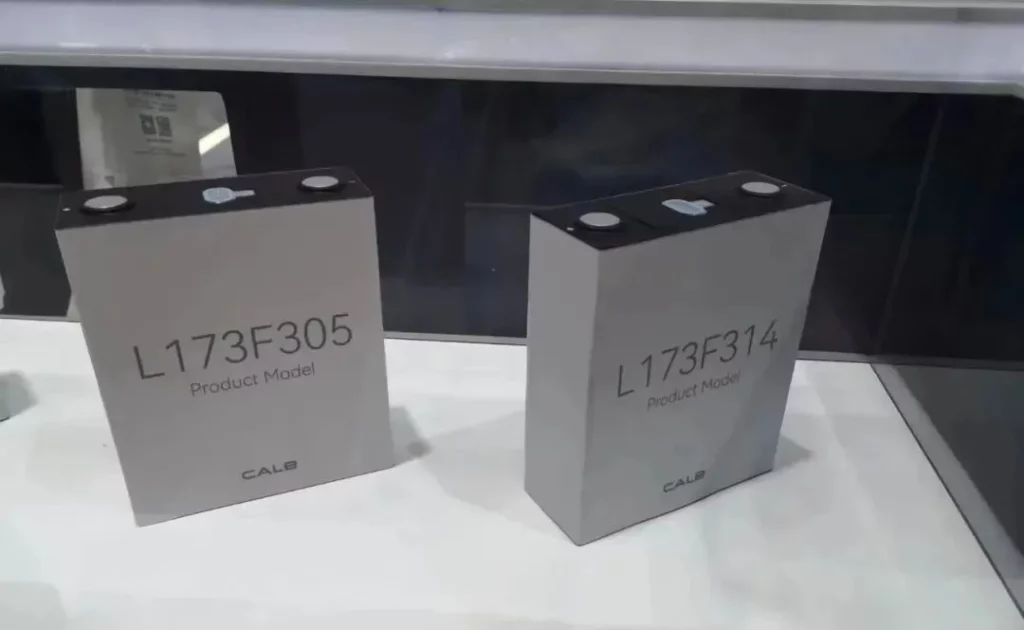

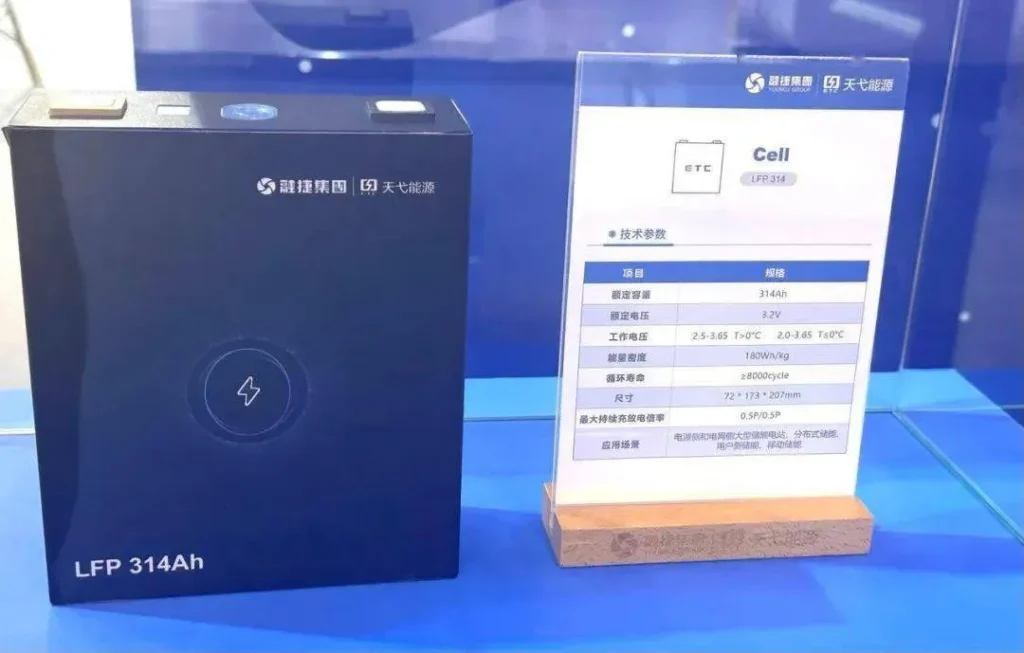

MB31

The EVE MB31 has a cycle life of 8000 cycles at 0.5C/0.5C. Giving it an estimated lifespan of up to 20-25 years

Capacity: 314Ah

Expected Real measured capacity when new 330+AH

Nominal Voltage: 3.2V

Advertised Cycle Life: 8000 Cycles

LIFEPO4 AUSTRALIA OPINION @ Thermally controlled environment

Cycle Life @ 1C : 4000 Cycles

Cycle Life @ 0.5C : 8000 cycles

Maximum Continuous Discharge 1C

Recommended Discharge 0.5C

Production technology – Stacking

Stacking vs Winding

Longer life span

The stacked battery cell has more tabs, the shorter the electron transmission distance, and the smaller the resistance, so the internal resistance of the stacked battery cell can be reduced, and the heat generated by the battery cell is small. The winding is prone to deformation, expansion and other problems, which affect the attenuation performance of the battery.

Comparing process of stacking battery vs winding

Stacking | Winding | |

Energy density | Higher. Higher space utilization. | Lower. There is a C angle, and the larger the capacity, the lower the utilization rate. |

Structural stability | Higher. The internal structure is uniform and the reaction rate is relatively low. | Lower. There is a C angle, which leads to uneven rate of internal reaction of charging and discharging. |

Fast charging adaptation | Better. The multi-pole plates are connected in parallel, the internal resistance is low, and the charge and discharge of large current can be completed in a short time, and the rate performance of the battery is high. | Poor. During the charge and discharge process, the degradation rate of the active material at the high temperature position is accelerated, and the other positions are rapidly attenuated. |

Safety | The risk is low. Stress distribution is more consistent, which keeps the interface flat and more stable. | Lower. Potential problems such as powder shedding, burrs, pole piece expansion, and separator stretching are easy to occur at the bend. |

Cycle life | Longer. Low internal resistance, relieve battery heating during fast charging, improve battery chemical system stability and prolong service life. | Shorter. It is easy to deform in the later stage, which in turn affects the cycle life of the battery. |

Productivity | Large-capacity batteries are generally low, mainly 6-8PPM. | Higher, generally at 12-13PPM. |

Yield | Low, the glitch problem is prominent. | Higher automation, higher yield rate, higher number of pole pieces. |

Process maturity | Low, the number of pole pieces is large, and the investment in equipment is large. | Higher, fewer pole pieces, mature equipment and low investment cost. |

Summary of new technology

Technologies such as low-expansion anode materials, full tab design, electrode surface treatment, and flexible electrode forming help resolve liquid infiltration challenges for large cells, enabling comprehensive safety protection and high cycle life through heat insulation, diffusion prevention, pressure relief

What to choose for a battery with the longest lifespan.

EVE MB30 Automotive A+ verified cells directly supplied from EVE, not via a third party, not via Alibaba, and not from most resellers and battery pack manufacturers including almost all battery builders in Australia and China, unless they can provide you with a) the official eve delivery report for the cell purchase, and b) evidence that the QR code is genuine and not re-lasered.

The B grade to A grade problem is going to be larger with the new models the LF280K v3 which is actually the MB30

A genuine QR code should be shiny behind the data that has been printed.