The Lifepo4 QR code B to A Grade problem

Q. What is a QR Code?

A. Its a 3D barcode

Q. What is a Barcode?

A. A visual representation of data

Q. Can a barcode be scanned to verify authenticity of unique products?

A. NO! A QR code does NOT authenticate product genuineness because it can be easily copied or duplicated by anyone.

Put Simply, if I have some text or numbers, I can quickly and easily generate a QR code. It is static data. It does not connect to EVE or any other manufacturer.

Q. Why I keep writing these articles over and over?

Part 1

I am observing that most sellers in Australia (Melbourne, Sydney, Rockhampton, Perth, and Brisbane) sell B grade cells as A grade. They either don’t care, or they don’t know themselves. It’s really disappointing.

I have to defend our own business sometimes, yet those same people attacking me are under the impression that the other sellers are selling genuine products, but I KNOW they aren’t.

a) I know because I have seen their cells in person, and I have seen the packaging. I can see they are buying from QSO, Basen, Docan, or EEL by the boxes, the stickers, the busbars, and the QR CODE! b) I have spoken to most of the sellers personally. c) I have seen the evidence over and over again.

Part 2

I have always known what a barcode and therefore a QR code is. I have personally worked in stock control systems since I was a teenager and in IT for years. I sold and supported stock control systems. We work with barcodes all day, and we know what a keyboard wedge is. (I know that 99.8% of people do not.)

Part 3

I only recently realized that most (not all) people do not understand what they are or how they work.

I’ve watched multiple people scan the code, thinking they were connecting to an authenticity server or something. Recently, I actually watched a guy scan his “known fake” jacket, which had a QR code on it, and I finally realized that people just don’t understand this technology in general.

Let me say this in BOLD red text!

QR CODES DO NOT AND CAN NOT VERIFY AUTHENTICITY

QR Codes for DUMMIES

Below this paragraph I have given you a QR code generator. You can make it do whatever you want within a set number or characters. It can create any data, like

If I have a spreadsheet with genuine QR codes, I can then generate a QR Code. If someone gets a hold of a spreadsheet like this one, attatched here. EVE uses a 24 character “string” of numbers and letters as their identifier. ![]()

Click it to download the spreadsheet of real QR codes, from a real EVE spreadsheet

Use this tool in orange, to create your own EVE barcodes using the Spreadsheet.

In Depth detail of QR codes

The amount of text a QR code can hold depends on the version and error correction level. Here’s a general idea:

- A standard QR code (Version 40, the largest version) can hold up to:

- 7,089 numeric characters

- 4,296 alphanumeric characters

- 2,953 binary (8-bit) bytes

However, practical QR codes used in everyday situations usually hold much less data to ensure they are easily scannable.

For best results, it’s advisable to keep the text short, typically under 300 characters, to maintain quick and reliable scanning.

Summary

EVE and others like them use QR codes for internal tracking while manufacturing battery cells. They are not there for the end user, to verify the authenticity.

QR Code created with a QR Generator by LiFePo4 Australia

THIS QR will have the string of data “https://www.lifepo4.com.au” You can scan this with a camera app, or a QR Code scanner and it will take you to this website, it won’t work with the LIFEPO4 QR Scanner, because that app has been modified to interpret batteries only.

If you have the spreadsheet with genuine QR codes, You can then generate a QR Codes and upload them to the Laser Engraver, and every 5 seconds you can laser engrave a new QR code onto a B grade cell, making it appear as a genuine A grade product, that even matches the spreadsheet you are look at.

Stop thinking chinese people are not educated, the truth is that many chinese, over 100 Million of them hold college degrees, they are smarter that you, almost certainly. And it only takes a few to tell the others what to do. Just like an egineer would do in Australia to his subordinates. As of recent data, approximately 18.3% of Chinese people hold higher education degrees.

That means, that there are more educated people in china, than the entire population of USA and Australia combined.

It also means that there are at least 10-20 educated chinese people for every one of us.

Make your own judgement.

How to use a spreadsheet to generate and print new QR codes with a Laser

If someone (think shady chinese battery mafia figure) gets a hold of a spreadsheet like this one, attatched here. They can then upload the data onto the Laser Machine, then one by one, they will write over the top of the Invalid or B Grade QR Code. Thus making a Battery cell with 280ah appear to be a 330ah cell.

It is really simple, the entire process takes a few seconds at most per cell. I have seen a video of this being done, I did not have the ability to save that video, and I can not seem to find it no matter how hard I google, and Baidu it. The videos are private for obvious reasons. But they do exist.

The Process of QR code Re-Lasering

Q How does QR replacement take place, and who is doing it?

A. In china, there are vast warehouses full of products that did not meet specifcations for use in commercial or high voltage battery pack use. They are still batteries, and they work, but for how long I hear you ask?

“how long is a piece of string”

High Voltage Module and A grade Pack disassembled

QR CODES DO NOT AND CAN NOT VERIFY AUTHENTICITY

Summary

A QR code is like a sticker. Anyone can print the same sticker and put it on anything, so it doesn’t prove the product is real. Only trusted sellers, like us, can guarantee the product’s genuineness.

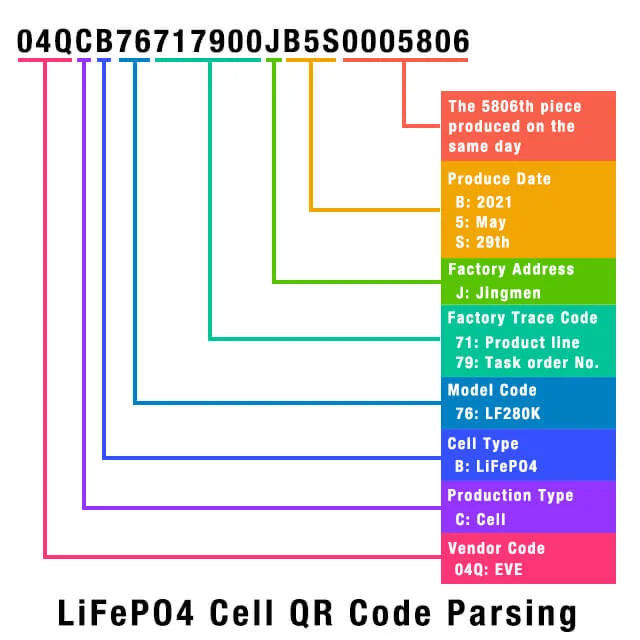

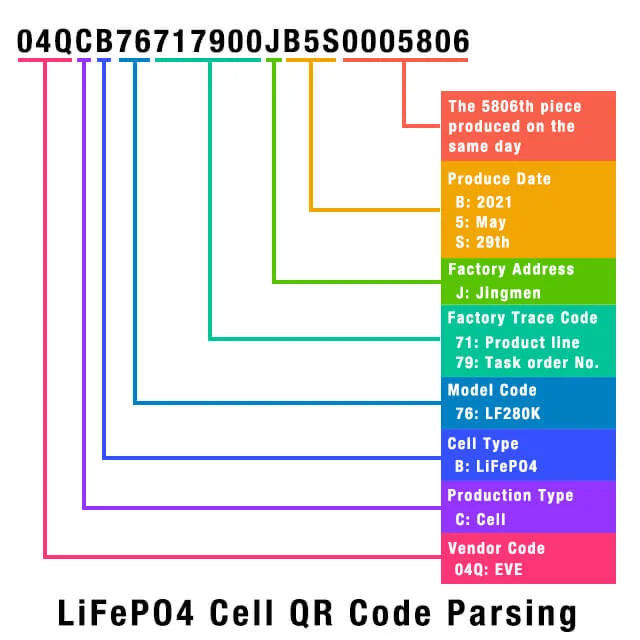

How to decode the data from EVE LFP Batteries

This is the EVE format of a QR code

Why a Lifepo4 QR Scanner app does NOT verify the Authenticity or Genuineness of Batteries

As we have discussed, a QR code is STATIC,

1. It does not connect to a database and return anything that can be used to know if the product is real or fake.

The Lifepo4 QR Scanner App, has a database, (think of it as a big spreadsheet. The database contains all the cell models, and some logical programming for the app to be able to decode all known QR codes. The user who created this app, did this to assist the community to try to know what product of battery cells, and where they were made and what capacity they were.

He has been able to gather enough data to make it work for the most popular manufacturers.

Once he has this image and others like it from the other manufacturers, he can very easily decode the important data, and that will return you a result on what that QR is supposed to be attached or printed on. (notice I said supposed)

|  |

Why Does all this even matter?

In a high voltage battery pack, it’s crucial that the batteries in series are matched and high quality because:

- Balanced Performance: Matched batteries ensure consistent performance, as each battery will charge and discharge at the same rate.

- Safety: High-quality batteries reduce the risk of failures, such as overheating, leaks, or explosions.

- Longevity: Using matched and high-quality batteries extends the overall lifespan of the pack by preventing weak batteries from causing the entire pack to degrade faster.

- Efficiency: Ensures that the battery pack operates at optimal efficiency, providing reliable power output without losses due to imbalance.

By ensuring batteries are matched and high-quality, you maintain the safety, efficiency, and durability of the high voltage pack.

But wait there is more!

If a single battery cell in a high voltage pack is faulty, it impacts the entire pack because:

- Chain Reaction: In a series configuration, the current flows through each cell in the chain. A faulty cell disrupts this flow, reducing the pack’s overall performance.

- Reduced Capacity: The faulty cell limits the pack’s capacity to the weakest cell, causing the whole pack to discharge faster and reducing its overall capacity.

- Safety Risks: A single faulty cell can overheat or fail, potentially causing damage to adjacent cells and posing safety hazards like fires or explosions.

- Increased Wear: The healthy cells are forced to compensate for the faulty one, leading to uneven wear and shortening the lifespan of the entire pack.

In summary, a single faulty cell can degrade the performance, capacity, and safety of the whole pack, highlighting the importance of ensuring all cells are high quality and well-matched.

Now the best way to explain this. using math

if you have 16 cells in series, all of which are 330ah, though a single cell has only 150ah of capacity, then the entire pack will loose 55% of its capacity.

In this example the single cell, limits the pack to a total of 16 x 150ah. Making your pack only 7.6Kwh, when it should be 16.8kwh.

In dollars in todays market, this would mean,

A $5000 investment would loose $2750 in value.

Making your battery worth only $2250

Not only this but the cell will continue to cause problems, causing your power to cut off regularly, and remain out of balance, and it will strain every other component in your pack.

Not only this but the cell will continue to cause problems, causing your power to cut off regularly, and remain out of balance, and it will strain every other component in your pack.