Comprehensive Guide to Battery Management Systems (BMS): Comparing JBD, JK, PACE, Daly, and More

In today’s rapidly expanding energy storage market, Battery Management Systems (BMS) play a critical role in the health, safety, and performance of lithium batteries. Whether you are building a battery for a solar setup, electric vehicle (EV), or DIY energy storage system, choosing the right BMS is essential for managing battery performance, extending lifespan, and protecting against potential hazards.

This guide will delve into some of the most popular and well-regarded BMS options available in the market, including JBD, JK, and Daly, analyzing their features, reliability, and overall performance. We’ll also highlight the pros and cons of each system to help you make an informed decision based on your specific requirements.

What is a Battery Management System (BMS)?

A BMS is an electronic system that manages a rechargeable battery, such as lithium-ion or lithium iron phosphate (LiFePO4), by controlling key functions like charging, discharging, temperature, and overall safety. The BMS ensures that the battery operates within safe limits and helps prolong its lifespan by balancing the cells and protecting against issues like overvoltage, undervoltage, and overheating.

Popular BMS Brands Overview

The BMS market is vast, with many different manufacturers offering various models ranging from budget-friendly basic protection systems to advanced smart BMS options with sophisticated features like Bluetooth connectivity and active balancing. Let’s explore some of the most popular brands:

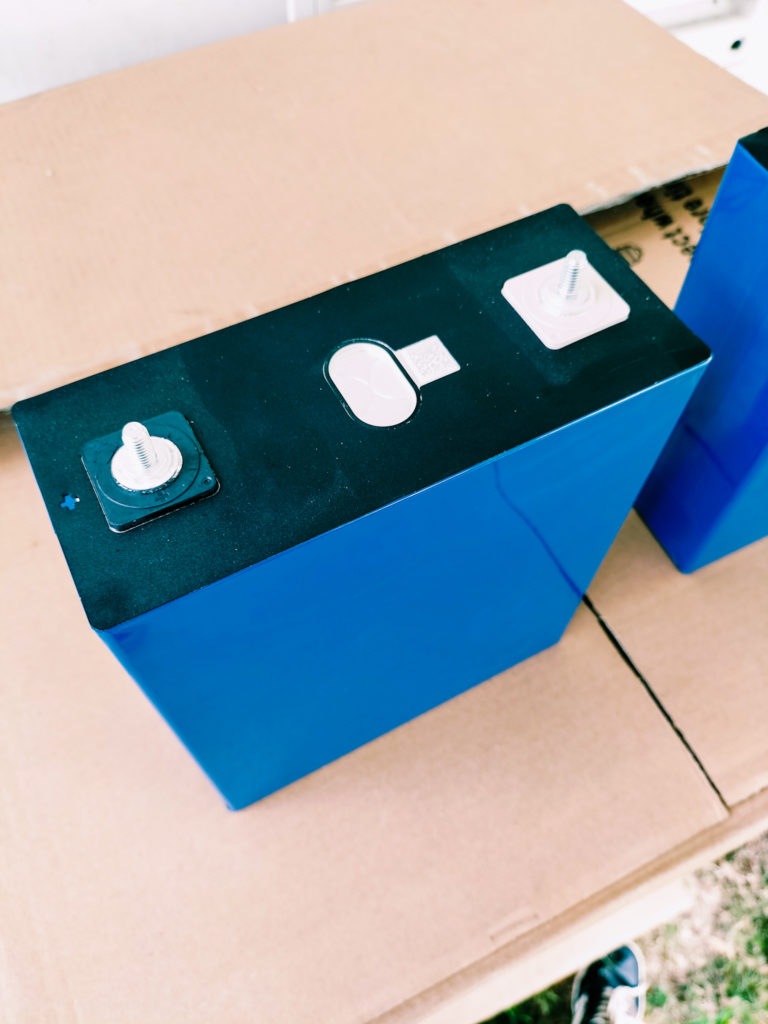

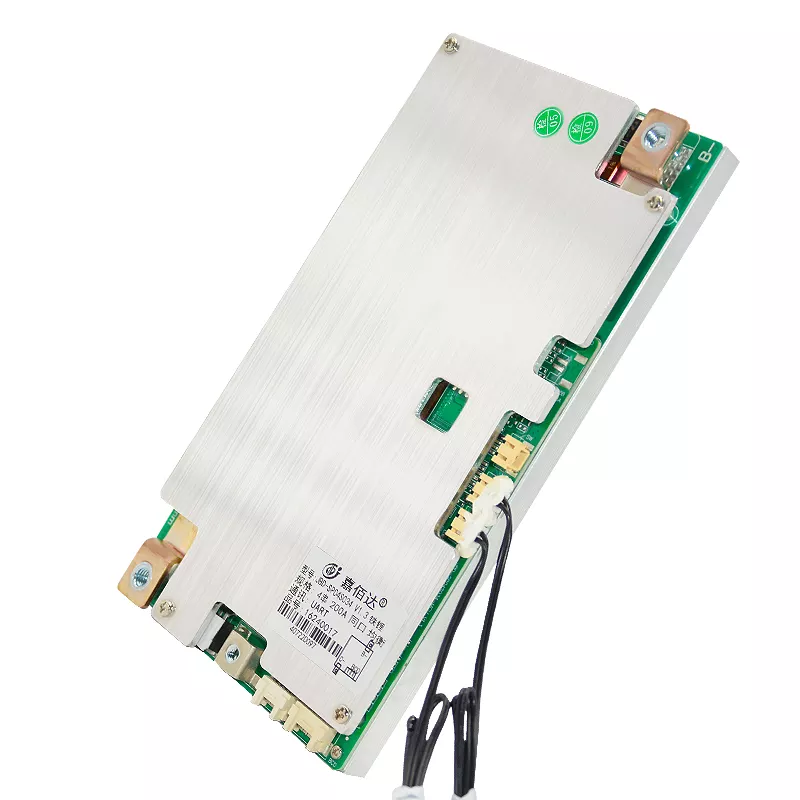

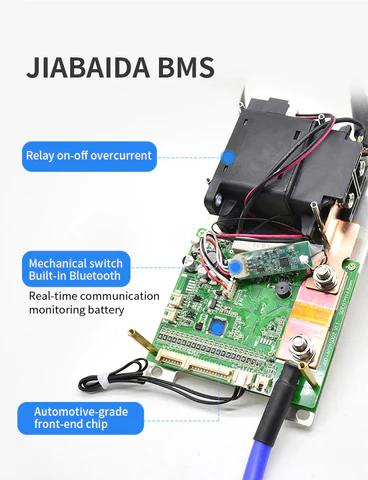

1. JBD BMS (Jiabaida BMS)

Overview:

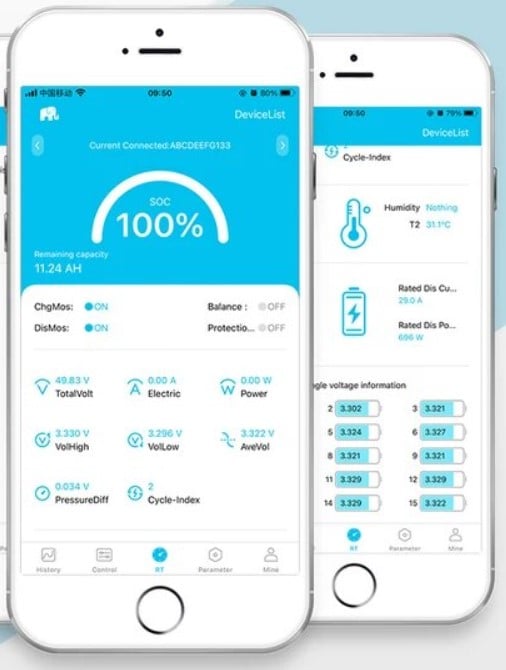

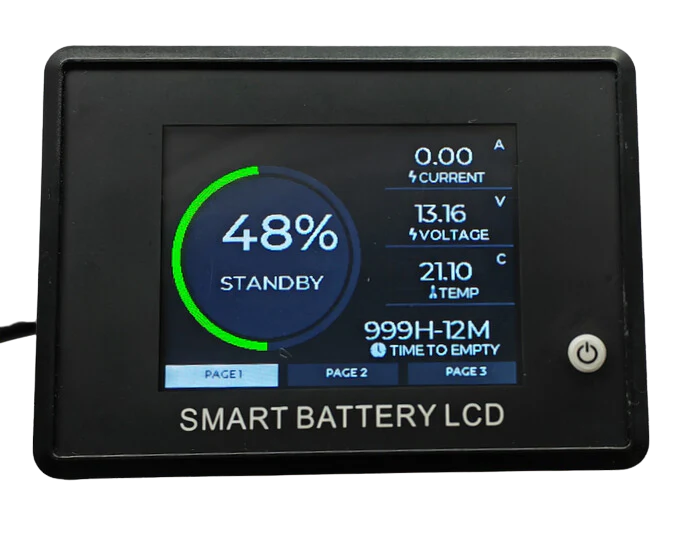

JBD is a popular choice among DIY battery builders and professionals alike. Known for its reliability and affordability, JBD offers a wide range of BMS products suitable for everything from small battery packs to large energy storage systems. It also features smart BMS options with Bluetooth, providing real-time monitoring and control through mobile apps.

Support for Victron, DEYE, Growatt and many other inverters.

Key Features:

- Available in 12.8V to 48V(51.2V) configurations, with various amp ratings.

- Both Smart BMS with Bluetooth connectivity for monitoring battery status via an app and Regular BMS, set and forget!

- Robust passive and active balancing models to keep cell voltages even.

- Comprehensive protection against overcharge, over-discharge, and over-temperature.

- Configurable parameters via PC software or mobile app.

Pros:

- Cost-effective with very reliable performance.

- Smart features like Bluetooth monitoring and mobile app control.

- Flexible configuration options.

Excellent Accuracy for SOC calculations - Available in high current ratings, suitable for large packs.

- Regular firmware updates improve functionality.

Cons:

- Slightly more complex to set up compared to simpler BMS units.

- Bluetooth connection range can be limited.

- Lack of detailed user manual support for first-time users.

Best For:

JBD BMS is well-suited for both DIY enthusiasts and professional battery builders who need reliable, affordable BMS with smart monitoring features. Ideal for medium to large battery packs in solar, RV, and EV applications.

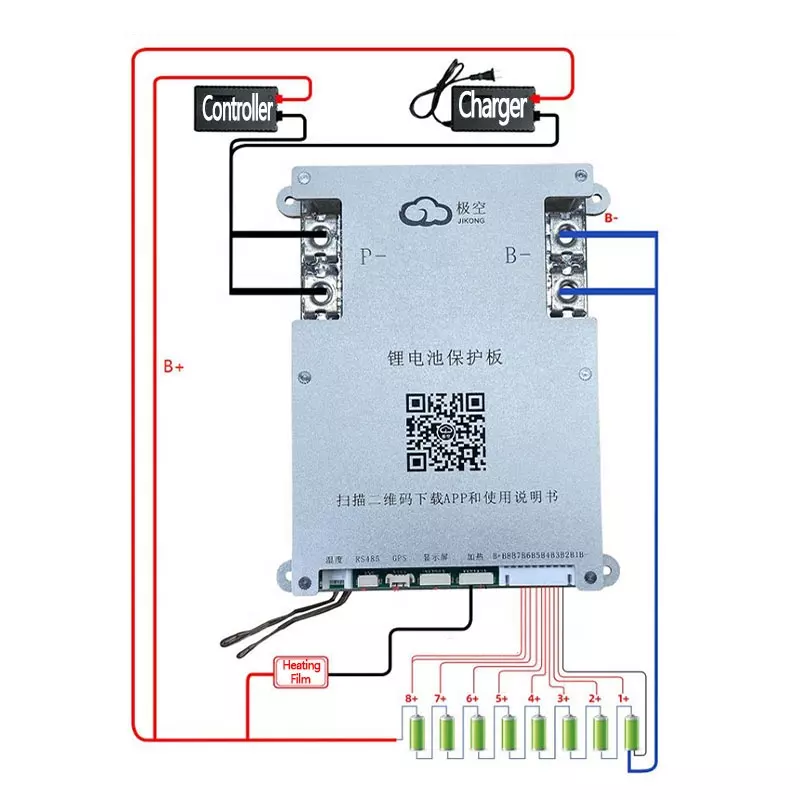

2. JK BMS (JiKong BMS)

Overview:

JK BMS is one of the most advanced BMS systems on the market, especially popular among energy storage professionals. It is known for its robust features, including active balancing, high customization options, and detailed data monitoring. JK BMS is highly regarded for its accuracy, durability, and flexibility, making it ideal for large-scale and critical battery systems. Support for Victron, DEYE, Growatt and many other inverters.

Key Features:

- Active balancing (dynamic cell balancing) ensures cells are equalized during operation.

- Bluetooth connectivity for real-time monitoring via a mobile app.

- Configurable protection parameters for precise control over charging and discharging.

- Software is good, but not perfect, and support has been poor in 2024 for the new model

Pros:

- Excellent active balancing capabilities reduce cell degradation and extend lifespan.

- Detailed monitoring and data logging for precise control.

- Widely customizable for different applications off-grid systems, and commercial setups.

- Rugged design with high current and voltage tolerance.

- Good accuracy for professional energy storage projects.

Cons:

- More expensive than basic BMS units.

- Higher learning curve for those new to BMS systems.

- Requires more time to set up and configure.

- Quality of materials may be lower, than JBD

- Software has been buggy.

Best For:

JK BMS is the go-to choice for large-scale, critical energy storage applications where active balancing and precise control are necessary. It is ideal for professional setups, commercial energy storage, and high-performance EVs.

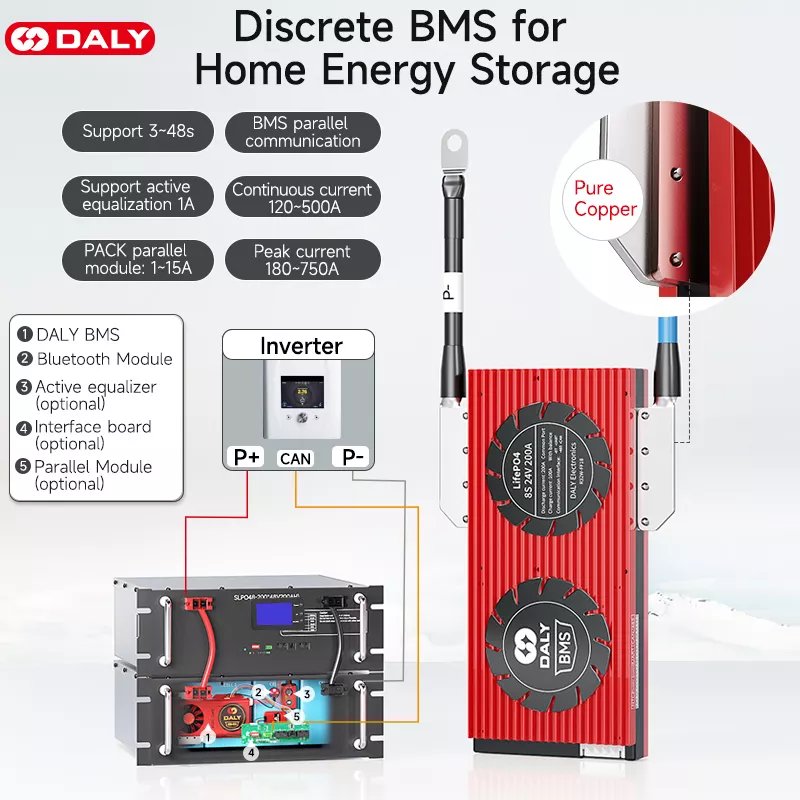

3. Daly BMS

Overview:

Daly BMS is another popular option, especially in the DIY space, due to its affordability and basic functionality. Daly BMS is often used for simple battery systems that don’t require the advanced features seen in more expensive systems like JK or JBD. It offers basic protection for lithium batteries, making it suitable for small energy storage systems or low-demand applications.

250A 300A 400A 500A

Key Features:

- Basic protection: overvoltage, undervoltage, over-temperature, and short circuit protection.

- Available in 12V to 48V configurations with various amp ratings.

- Passive balancing for maintaining cell voltage consistency.

- Compact design, easy to install, and cost-effective.

Pros:

- Easy to buy

- Simple to set up and use.

- Basic cell balancing and protection features are sufficient for smaller setups.

- Widely available with many options for different voltage and current requirements.

Cons:

- Passive balancing is less efficient than active balancing.

- Less suitable for large or high-performance battery systems.

- Durability concerns for long-term use in critical applications.

- Active Cooling is unreliable

Best For:

Daly BMS is ideal for small-scale projects, DIY enthusiasts, and applications where basic protection is sufficient, such as small solar setups, electric bikes, or RVs. However, it may not be the best choice for large or critical energy storage projects.

4. PACE BMS

PACE BMS is designed to offer precise control and management over battery packs, particularly in scenarios where safety, durability, and advanced functionality are critical. It competes with other high-end BMS solutions like JK and REC, offering features that cater to both small and large battery systems. The focus is often on high voltage and high current capabilities, active balancing, and detailed monitoring.

PACE BMS is trusted in many server rack batteries, and is very similar to many other professional grade UPS and ESS storage BMS, with communication with Inverters and other parallel batteries one of the strengths of this product. Support for Victron, DEYE, Growatt and many other inverters.

51.2v

Key Features of PACE BMS:

- Passive Balancing: Ensures cells within the battery pack remain balanced, improving the pack’s longevity and performance.

- High Voltage and Current Support: PACE BMS is designed to handle larger battery packs, making it suitable for industrial energy storage systems and EVs.

- Smart Monitoring: Bluetooth connectivity, Wi-Fi integration, and real-time monitoring through mobile apps and dedicated displays.

- Scalability: PACE BMS supports a wide range of voltages and capacities, making it versatile for projects of various sizes.

- CAN Communication: Allows integration into more complex systems and communication with other components, such as in electric vehicles or sophisticated solar setups.

- Configurable Protection Settings: Advanced protection for overvoltage, undervoltage, over-temperature, and current surges, with configurable thresholds.

Pros of PACE BMS:

- Advanced Features: PACE BMS offers high-end features like balancing, real-time monitoring, and CAN communication, making it suitable for professional or industrial-grade systems.

- High Reliability: It is built with a focus on safety and durability, ensuring optimal performance even under demanding conditions.

- Great Scalability: Suitable for both small and large battery packs, offering flexibility across different applications.

- Detailed Monitoring: Real-time feedback on battery health and performance ensures better maintenance and control.

Cons of PACE BMS:

- Higher Cost: PACE BMS tends to be on the more expensive side compared to options like Daly or JBD, which may not make it ideal for DIY enthusiasts or small-scale projects.

- Complexity: Due to its advanced features and configuration options, PACE BMS has a steeper learning curve and may require technical knowledge to set up and manage effectively.

- Overkill for Simple Systems: For small or low-demand projects, PACE BMS may offer more features than necessary, which could result in unnecessary costs.

Best For:

PACE BMS is ideal for large, complex energy storage systems, electric vehicles, or any application that demands high reliability, precision, and detailed monitoring. Its advanced features and robust safety mechanisms make it a top choice for critical systems where performance and safety are paramount.

5. Other Popular BMS Options

Overkill Solar BMS:

Specifically designed for DIY solar energy storage systems, Overkill Solar BMS is known for its user-friendly interface and detailed monitoring features. It offers Bluetooth connectivity and a built-in display for real-time stats, making it a favorite among home solar system installers. Overkill uses modified versions of the JDB BMS, in some cases the same BMS.

REC BMS:

One of the high-end options, REC BMS, is designed for advanced applications requiring detailed control, real-time data, and integration into large, complex systems. It supports both passive and active balancing and is highly customizable, often used in commercial energy storage projects.

Pros and Cons Comparison Table

| BMS Brand | Key Features | Pros | Cons | Best For |

|---|---|---|---|---|

| JBD | Smart BMS, Bluetooth, balancing, overcharge/over-temp protection | Cost-effective, smart features, reliable performance | Complex setup, low balance currents | DIY and professional setups for solar, EVs, and large battery packs |

| JK | Active balancing, high current, customizable parameters | High current Active balancing, touchscreen, Bluetooth | Expensive, steep learning curve, software issues | Small-scale energy storage, EVs, commercial energy applications |

| Daly | Basic protection, passive balancing, over-voltage/under-voltage | Easy to buy, easy to use, basic protection | Lacks advanced features, limited balancing capabilities | Small DIY projects, basic solar setups, electric bikes |

| PACE | Bluetooth, passive balancing, over-temperature protection | High price, difficult setup, Bluetooth monitoring | Lacks advanced features like active balancing, not DIY friendly | Commercial scale solar setups, low-voltage energy storage systems |

| REC | Active balancing, high customization, detailed monitoring | Highly customizable, integrates into large systems, active balancing | Very expensive, complicated setup overly complex | Large commercial projects, grid-connected systems, high-end EV setups |

Final Thoughts: Which BMS is Right for You?

When it comes to selecting a BMS, the right choice depends on your specific project requirements. Here’s a quick summary to help guide your decision:

- For DIY enthusiasts or small battery systems: JBD offers the most budget-friendly option with basic protection features. It’s ideal for simple projects like e-bikes or small solar setups.

- For advanced DIY and professional setups: JBD and JK BMS is a great middle-ground option, providing smart features like Bluetooth monitoring, good balancing, and flexibility in configuration. It’s a solid choice for medium to large battery packs.

- For large-scale or critical energy storage systems: PACE BMS is the gold standard, offering active balancing, high current handling, and extensive monitoring capabilities. It’s perfect for large energy storage projects, EVs, and commercial applications where reliability and performance are paramount.

Ultimately, the best BMS for your needs will depend on the complexity and scale of your project, as well as your budget. Each BMS option has its strengths, and understanding your specific requirements will help you choose the most suitable one for your system.

Ready to Take Your Energy Storage to the Next Level?

At LiFePO4 Australia, we specialize in helping you choose the best components for your battery systems. Whether you’re looking for a high-end BMS or just starting out with a basic battery pack, we’ve got you covered with expert advice and top-tier products. Contact us today to learn more about our range of BMS options and how we can help you build the perfect battery system!