LIFEPO4 A Grade B Grade Information

So you want to know what you are buying? A, B or even C grade battery cells. Well, the truth will likely shock you. But a typical failure rate for cells in the 200AH+ range is currently between 2-10%. For a Tier 1 manufacturer live CATL, EVE, CALB the rate is lower. For tier 2 and 3 manufacturers it can reach 10-20%. And it’s this high, because it’s very difficult to produce cells of this size perfectly.

For reference the reject rate on 18650 cells by Panasonic, and Samsung is more like 0.001%. So, you can see there is a huge difference, there is also an element of the cathode mixture being more difficult to

So what makes a cell A Grade?

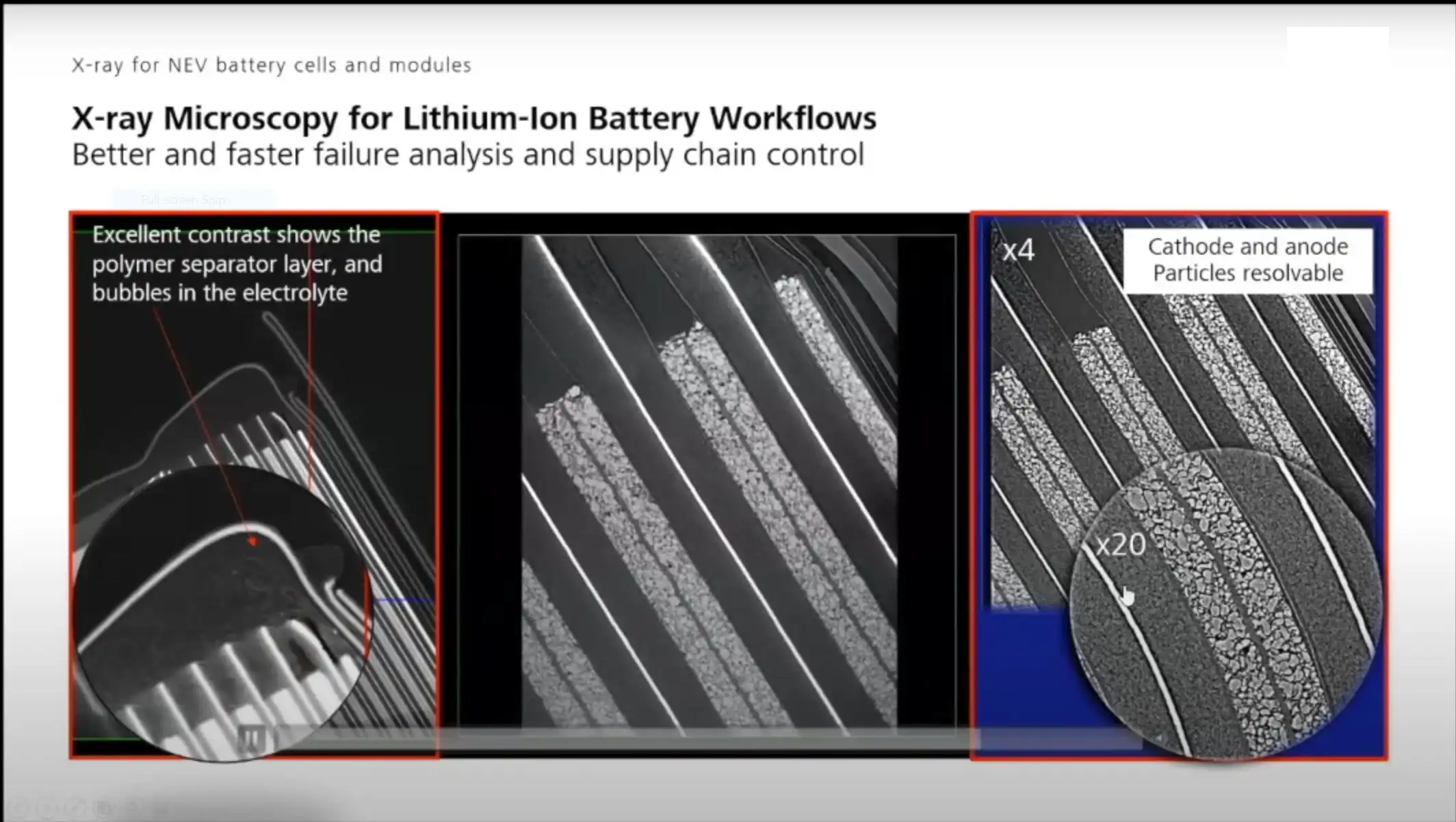

Testing over a period of about 3-4 weeks, it is done in the factory, the cells are cycled multiple times, with an initial charge that is also to electroplate the lithium onto the cathode and anode. One of the best test’s used is the X-RAY test, and this test in particular allows the manufacturer to see into the future. And see obvious problems early.

It’s what differentiates the A grade and B grade product, As we have always known, A good B grade product is likely to only last somewhere between half to 1/8th of a good A grade product, however this does come many caveats, especially to do with how the cells are managed and treated in their service life.

IF YOU TREAT THEM POORLY they will degrade much faster

Some of the brands that make the same LF280 and LF302 cell are CATL, EVE, Li Shen, Hithium. CALB, Ganfeng, ETC, Sundowa, REPT and actually a few more. This is an identical cell, only the defect rate and quality of the chemical composition are varied, things such as the purity of the Lithium Carbonate vary. It’s a little bit like the paint job you might get across different car manufacturers. Making Lithium cells is extremely precise. All the machinery must be running at the optimum in order to get the defect rate lower.

Where do all the A and B grade cells go?

A grade goes mostly to Electric Vehicles. Trucks, Buses, Cars, Trains, but also for Grid Storage, for homes and sometimes even RV’s and Caravans. They also go into some brand name products, such as Victron, Deye, Ecoflow, and our own brand LiFePro.

Why do they sell B grade?

One of the challenges that battery manufacturers face is the quality control of their products. Not all cells are created equal, and some of them may have flaws or defects that prevent them from being used in vehicles or other high-performance applications. These cells are usually classified as Grade B or lower, and they represent a significant loss of revenue for the producers. However, there is still a market for these lower-grade cells, especially for less demanding uses such as power banks, solar generators, or DIY projects. The LF280 and LF304 are two examples of large-format cells that have a high defect rate, up to 10%, which means they cannot meet the strict standards for vehicle use. But they can still offer a decent capacity and power output for other purposes, and they are sold at a lower price than the Grade A cells.

B grade cells are a common choice for stationary applications, such as DIY battery projects. Unlike C grade cells, which often have visible flaws and may come from recycled sources, B grade cells look flawless and have minor internal defects that do not affect their performance significantly. There is no regulation that prohibits the use of B grade cells for battery storage, and many people take advantage of this to build their own battery packs at a lower cost.

If you are wondering who is the judge of B and C, well that is something that has emerged over time, across the industry, they needed a way to label the quality of the cells, as the buyers become more educated especially with the forums such as DIYSOLARFORUM hosted by Will Prowse in the USA.

My personal opinion of forums and Facebook is that they are not a good place to get accurate information

The lithium battery industry is complex and constantly evolving. I have spent years studying it and updating this article several times to keep up with the latest developments. Don’t trust everything you see on Facebook. Most of it is outdated or inaccurate, and distorted by repeated sharing.

EVE marking the letter B on cells?

As we have been in communication and sales with EVE over the past 48 months, we have a direct line to the inner workings of the EVE battery cells.

- The price of new A Grade EVE cells is about 50% more expensive than can be purchased in B grade

- EVE’s brand is very valuable to them, and so they are printing the letter B on all cells that don’t meet the grading cut for what we know as A grade cells. This is something they have not done in the past. And all new stock from May 1 2022 will be marked with the letter B if it is not an A grade product.

- MOST SELLERS ARE REPLACING or RE LASERING QR CODES, Unfortunately, it is already very easy to find cells without the B etched into the QR code. And if you aren’t educated you are likely buying B grade cells, that you are told are A grade.

- We also know that in these LiFePo4 factories there is always 2-10% of cells that don’t meet the cut for what we refer to as A Grade.

December 2023 update : We have now learned that when a factory opens it goes through a period of months where as many as 50% of large cells such as the 300ah, are classed as B grade. This yield continues to rise until it reaches about 85-90%. We finally have an answer to how there are so many B grade cells on the market. - A Grade cells can be for cars, Electic Buses and Trucks, along with BESS (battery energy storage system) use where the C rate maybe higher than 0.5C

- Remember that EVE is a much larger company than you might realize, they have multiple factories of different ages, and as each factory is built, the technology is upgraded to be better than it was in the past. For example its very likely the new Version 3 cells are a new factory altogether!

More Evidence? I hear you ask. So what is the grading process?

Let’s use A Grade EVE LF280K cells as an example. EVE has not confirmed what the grading process is in writing, but it is a mixture of things

- Voltage at rest

- Voltage under load

- Voltage recovery

- Appearance

- Internal Resistance

- Capacity

- X-RAY Test

- An LF280K v3 is likely to need to pass 300AH in capacity at a 0.5C rate to meet the requirements for Grade A. In other words, it could be from 300-310AH in capacity when brand new to be what we call an A Grade.

- Occasionally an Automotive grade cell can actually test under 300 AH but have excellent voltage. This is because technically they measure the cells in Watt hours and not amp hours. But for simplification, I’ve just adjusted the numbers as they are what we typically receive.

Many YouTubers mistakenly believe that if they discharge at a rate of 0.2C that is how they can get the accurate capacity. This is partly wrong because the cells are tested in the factory at either 1C or 0.5C. This 0.2C discharge is not what the factory specifies in the datasheet, sometimes this is referred to as storage battery grade, but the truth is, that’s an invented term, to allow the resale of cells that failed from the factory according to the specification sheet and test results.

DATASHEETS are very often faked on marketplaces, and forums, and especially from poor quality sellers, looking to take advantage of anyone who isnt an expert.

B grade cells can have almost the same capacity (in Ah) and impedance (internal resistance) as Automotive grade cells WHEN they are brand new, making it difficult to distinguish between the two. B Grade cells are 30-40% less expensive than Automotive grade cells.

B grade cells are normally sold to Chinese companies for use in Solar storage, that is how they end up on Alibaba the buyers will do spot checks on the cells, almost never will they test all cells, as it is cheaper to send the odd warranty replacement than it is to test them all.

They are then resold on Alibaba as A Grade, and I’m yet to find any seller who doesn’t call them A grade (that should tell you something). this is the reason why 90% of cells sold in Australia are actually failed or rejected cells, because no one, ever wants to pay the price premium. It’s just how it is. And only the most experienced buyers, order our A grade product from a professional seller, or directly in bulk from the factory. Usually with very high shipping charges. I recently obtained a quote for 20 x EVE LF280K v3 cells and the shipping was over $1500AUD alone. Not including the battery cells themselves.

This is just robbery. This along with a warranty that is useless as you can’t return lithium battery cells to china without extreme cost and dramas, meaning you are just about always better choosing an importer to purchase from, as they are held to Australian Consumer Laws, and must supply a warranty that is reasonable. For Automotive grade cells this might be as long at 5 years.

When you compare costs on the international market to prices on NMC and LFP cells imported in Australia, it’s easy to see that a significant portion of the NMC and LFP cells imported are B-grade cells. One of the main reasons for this has been fierce price competition among battery pack assembly businesses, and this is an enormous growth industry. From 2015 to 2020 the number of factories rose from 4 to 181. And this is accelerating, almost every week, there are multiple announcements of factories 10 times the size of previous ones.

Certified A Grade vs. B Grade Cell Performance

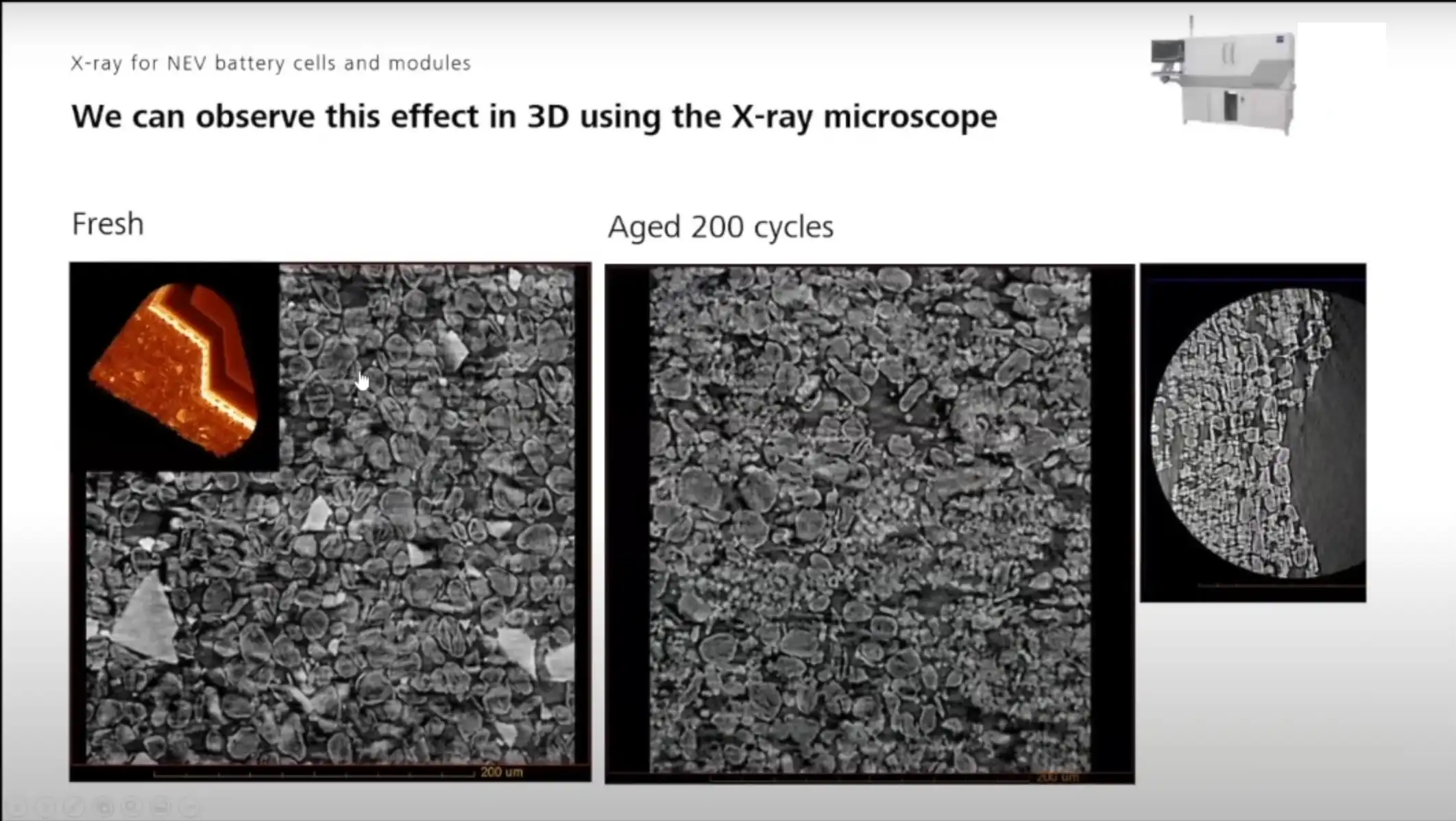

Fade/Cycle Life of Capacity – A lithium-ion cell’s cycle life is defined as the number of charge-discharge cycles at 80-100% depth of discharge (DoD) until the cell’s retention capacity reaches 70% or 80% of its initial capacity. B grade cell’s capacity fade is higher, which means it has a shorter cycle life. When compared to A grade cells, B-grade cells have a faster rate of capacity fade, which can be anywhere from 50-90% faster. That means that if an A-grade cell is designed for 11 years of life, which the LF280K is expected to last to 80% capacity. A B-grade cell might hit that point at anywhere from 2 to 5.5 years. There of course are many factors at play, but you can do some math, and work out the TCO (total cost of ownership) from this information.

My personal view is that there is no magical new chemistry that will overtake Lifepo4 in the next 5-10 years. with Sodium-Ion batteries slated for mass production from 2023 onwards, and very unlikely to be at cost parity until around 2028-2030. And then they may be only 20% cheaper, but at this point in time, I cannot predict the future with any certainty.

Quick Summary

LEAD ACID vs LFP?

Lead-acid batteries are no competition to LFP. They are inferior in every possible way.

| LEAD-ACID AGM | LITHIUM-ION | |

|---|---|---|

| Installed capacity | 100 KWh | 50 KWh |

| Usable capacity | 50 KWh | 50 KWh |

| Lifespan | 500 cycles at 50% DoD (Depth of Discharge) | 8000 cycles at 100% DoD |

| Number of installations | 6 (1 + 5 replacements) | 1 |

| Battery cost | $60 000 ($100/KWh x 100 x 6) | $12500 ($250/KWh x 50 x 1) |

| Installation cost | $12 000 ($2000 per install x 6) | $12500 (one shot install) |

| Transportation cost | $6 000 ($1 000 per transport x 6) | $1 000 (one shot install) |

| TOTAL COST | $78 000 | $13500 |

| Cost per usable KWh per cycle | 0.42c / usable kWh (78 000 / 3000 / 50) | 0.031c / usable kWh (23 000 / 6000 / 50) |

In summary, the total cost of ownership per usable kWh is about 10 times cheaper for a lithium-based solution than for a lead acid solution. And that is not taking into consideration the huge losses due to absorption, you would need to size your solar system at least 30% larger with the best Lead Acid System. Meaning even more additional costs!

It does NOT make sense

Do you want to know more about Internal Resistance?

Impedance, commonly known as internal resistance, is inversely proportional to cell performance. The lower the impedance, the higher the charge and discharge rate of the cells. Because electric vehicles require rapid charging and high power discharge, EV Grade cells have a lower impedance than Energy Storage Grade cells.

The impedance of the cells increases when they are charged and discharged. The cell’s impedance reaches a threshold where it is no longer usable for a particular application (such as EVs). It is then disassembled and utilised as a part of a second-life battery to power applications with a lower charge-discharge C rating (such as Energy Storage Systems). The rise in the number of B grade cells is faster than the rise in the number of A-grade cells.

Understanding Automotive vs B-Grade in LFP Batteries

What makes some LFP batteries perform like champs—and others get downgraded?

Introduction

Lithium Iron Phosphate (LFP, or LiFePO₄) batteries have surged in popularity in applications ranging from electric vehicles (EVs) to solar energy storage. They offer many advantages: safety, long cycle life, stable chemistry, lower cost materials (no cobalt), and good thermal stability.

However, not all LFP batteries are created equal. Even when labeled “LFP,” there can be a wide spread in quality, performance, and lifespan. One major distinction is between “Automotive / A-Grade” cells (or modules) vs “B-Grade” (or downgraded, off-spec) ones.

If you’re a consumer, buyer, enthusiast, or engineer, knowing what differentiates Automotive (“A-Grade”) LFP from B-Grade is critical. It affects safety, reliability, total ownership cost, and how well the battery will perform under harsh conditions.

Basic Concepts

Before we dig into differences, let’s establish key terms and what people usually mean by “A-Grade” vs “B-Grade” in the context of LFP.

- Cathode / Chemistry: LFP uses lithium iron phosphate as the cathode. It’s very stable, safe, but has lower intrinsic electronic conductivity and slightly lower energy density vs chemistries like NMC.

- Anode: Typically graphite, same as other Li-ion battery types.

- Cycle Life: How many full charge/discharge cycles before usable capacity drops (often to ~80% of original). A-Grade aims for high cycle lives (several thousand cycles under realistic conditions).

- Rate Capacity / Power Delivery: How fast the battery can be charged or discharged without significant voltage drop, heating, damage. Good rate capability is harder to achieve in LFP because of its lower electronic conductivity.

- B-Grade: Cells or batches that fail to meet certain high benchmarks (for Automotive / OEM use). Might pass initial tests (capacity, voltage range) but have elevated internal resistance, poorer cycle life, inconsistent performance, more “defects” (particle size variation, imperfect coatings, etc.).

- A-Grade / Automotive Grade: Cells that meet strict performance, safety, durability, and quality control standards demanded by automotive OEMs and high reliability applications.

Why LFP Has More B-Grade Rate Issues Than Some Other Chemistries (High Level)

To understand the distinction, you need to know what makes manufacturing LFP at high quality particularly challenging. Some high-level points:

- Electronic conductivity is low in pure LFP. Without extra conductive additives or coatings, electrons struggle to move, reducing power and increasing internal resistance.

- Lithium ion diffusion is constrained by particle size and the crystal structure. In LFP, ions move through olivine-structure channels which are relatively “tight” or direction-constrained; large particles or poorly connected structure slow diffusion.

- Coating (carbon) uniformity and quantity matters a lot. If the carbon coat is patchy, thick, or uneven, parts of the cathode become “dead” (poorly conductive).

- Phase purity and defect density: Impurities, secondary phases, defects (e.g., antisite defects where Fe and Li sites are swapped) degrade lithium mobility or reduce available active material.

- Quality of electrode fabrication and cell assembly: Slurry mixing, electrode coating, drying, calendaring (pressing), stacking or winding, electrolyte filling—all must be well controlled. Even small defects (voids, misalignment, binder issues) can lead to weak spots.

- Formation, aging, and testing: How cells are “formed” (first charge/discharge cycles), whether they are aged or tested at high rates, whether they are subjected to temperature extremes—all that reveals which are weaker. A-Grade manufacturers test heavily; weaker ones may shortcut this and let defects pass.

Thus many LFP batches from smaller or less mature factories end up as B Grade—cells that work okay initially, but fail “gracefully” (i.e. faster degradation, poorer rate, weaker safety margins).

What Automotive / A-Grade LFP Suppliers Do

Now let’s move from general to what the top players do in practice to push yields for Automotive / A-Grade LFP very high. These are the kinds of practices that separate elite manufacturers from average ones.

| Area | Challenges | What Automotive / A-Grade Manufacturers Do to Overcome Them |

|---|---|---|

| Raw materials & stoichiometry | Getting the exact Fe, P, Li proportions; avoiding Fe²⁺/Fe³⁺ imbalance; avoiding contamination | Use precise precursor feeding; closed reactors; consistent quality suppliers; real-time monitoring of input purity; ICP / chemical analysis to ensure element ratios; strict vendor qualification. |

| Particle size, morphology, distribution | Large particles → slow Li diffusion; wide size distributions → inconsistent performance; irregular shapes can cause poor packing, more voids | Use advanced synthesis techniques (spray drying, hydrothermal, sol-gel, etc.) to control size (~100-200 nm often) and morphology; multi-step milling and sieving; process control to reject anything off spec. |

| Carbon coating / conductive network | Need uniform carbon coating; avoid thick “dead carbon” or patchy coating; conductive additive distribution; binder issues | Use fine carbon precursors (carbon black, graphene, nano-carbon) well dispersed; use sol-gel, CVD, or well-controlled pyrolysis; test coating uniformity (e.g. via microscopy); use conductive carbon networks; optimize binder mix to ensure mechanical and conductive stability. |

| Electrode fabrication | Slurry mixing, drying, calendaring, thickness uniformity; binder adhesion; porosity and density trade-offs | Strict process controls: controlled viscosity, uniform coating; drying schedules to avoid cracks or gradients; calendaring to set the right density/porosity; strict tolerance control; inline metrology; environmental control (humidity, temperature). |

| Cell assembly and sealing | Misalignment, electrode stacking/winding defects; poor electrolyte filling; sealing leaks; impurities introduced during assembly | Clean room or controlled environment for cell assembly; robot or precision machinery for stacking; vacuum or pressure filling of electrolyte; gas analysis to ensure low moisture, low oxygen; high quality thermal sealing. |

| Formation & quality testing | Weak cells may pass initial capacity test but fail on long-term performance, high rate, or harsh conditions | Extended formation cycling under various conditions (temperature extremes, fast charging/discharging, partial state of charge operation); impedance spectroscopy (EIS), internal resistance measurement; X-ray and CT scanning to detect internal defects; thermal stability tests; accelerated aging tests. |

| Sorting / Binning | Once batch is made, there’s variation—even in good factories. Cells must be sorted so only the best make it into Automotive use | Use multidimensional sorting: capacity, self-discharge, internal resistance, rate capability, thermal behavior; use machine learning or statistical control to bin cells; reject or downgrade cells with sub-par metrics to B-Grade. |

| Engineering and material improvements | Even in good process, certain intrinsic limitations remain (diffusion, conductivity) | Doping (e.g. adding small amounts of e.g., Mg, Ti, Nb) to improve Li diffusivity; surface coatings (Al₂O₃, ZnO, etc.) to stabilize interfaces; nano-engineering (composites, core-shell structures); optimized electrolyte formulations; advanced separator materials. |

Automotive / A-Grade vs B-Grade: What Buyers and Engineers Should Watch

Here are the key parameters and signs you can look at to tell if a cell/module is likely to be A-Grade (good) vs B-Grade (riskier):

| Parameter | Automotive / A-Grade Typical Specs / Behavior | B-Grade Issues / Signs to Watch Out For |

|---|---|---|

| Capacity (nominal at rated conditions) | High, close to design spec; tight tolerances (e.g. ± 5 %) at standard temp and standard current | Nominal capacity may be okay, but often only at low rates; at higher discharge or charge rates the capacity drops significantly |

| Internal resistance / impedance | Low and consistent across cells; good high-rate performance; small voltage drop under load | Higher IR; more voltage sag under load; higher heat generation; performance deteriorates under load |

| Cycle life | Thousands of full cycles with >80-90% retention; stable over wide temp range | Fewer cycles before degradation; faster decay; greater capacity fade; more sensitivity to temperature or charging regimes |

| Self-discharge and calendar life | Low self-discharge; stable over time; minimal swelling or gas generation | Higher self-discharge; swelling; capacity loss over storage; performance shift after idle time |

| Rate performance | Good performance even at high discharge/charge rates; good power density | Poor performance at high rates; overheating; more limits imposed in specification to avoid damage |

| Uniformity (cell-to-cell) | Tight statistical spread in key metrics (capacity, IR, rate, thermal behavior); batch consistency | Wide spreads; some cells significantly worse; more rejects; unpredictable behavior in packs |

| Safety / thermal stability | Good thermal runaway thresholds; stable heat behaviour; well-engineered thermal management; strong sealing; stable interfaces | More prone to hotspots; weaker separators or poor electrolyte; safety margins lower; possible defects leading to failure under abuse |

| Warranty & supplier documentation | Transparent test data; long warranties (years, number of cycles); performance guarantees; traceability | Shorter warranties; vague specs; sometimes performance only in ideal lab conditions; less third-party verification |

Deep-Technical Detail (for Engineers / Autodidacts)

Now let’s dig into the nitty-gritty: crystal chemistry, defect physics, coatings, conduction networks, formation protocols, etc.

Crystal Structure & Lithium Ion / Electron Transport

- LFP has an olivine structure (orthorhombic). Lithium moves in one-dimensional channels (the [010] direction). Fe²⁺/Fe³⁺ redox happens on the Fe sites, but electrons must hop via the Fe conduction paths and through conductive additives/carbon coating.

- Because conduction (both ionic and electronic) paths are constrained, particle size is critical. Diffusion length grows with √(time), so smaller particles = faster rates. Oversized particles or ones with internal defects (dislocations, grain boundaries) slow Li+ diffusion or create “dead zones.”

- Also, defect chemistry matters:

• Antisite defects: when Fe (or other atoms) occupy Li sites, this blocks Li channels. These defects are more common when synthesis is less controlled.

• Off-stoichiometry or secondary phases (Fe₂O₃, Fe₃(PO₄)₂, etc.) reduce the amount of active material.

✅ Breaking it Down

- “LFP has an olivine structure (orthorhombic)”

- Olivine refers to the crystal type: LiFePO₄ arranges itself in a rigid, orthorhombic lattice (a 3-axis, non-cubic crystal).

- This is what makes LFP so stable and safe—it doesn’t release oxygen easily (unlike NMC), which reduces fire risk.

- “Lithium moves in one-dimensional channels (the [010] direction)”

- Inside the crystal, lithium ions can only move easily along certain pathways (the [010] crystallographic axis).

- This means lithium diffusion is 1D, unlike NMC (which has 2D diffusion paths).

- Why it matters: diffusion is more sensitive to defects or large particle sizes. If the channels are blocked or too long, lithium moves sluggishly.

- “Fe²⁺/Fe³⁺ redox happens on the Fe sites”

- The energy storage mechanism is the iron atom switching between Fe²⁺ and Fe³⁺ oxidation states as lithium ions leave or enter.

- This redox couple is very stable, giving LFP its long cycle life.

- “Electrons must hop via the Fe conduction paths and through conductive additives/carbon coating”

- LFP has very poor natural electronic conductivity (about 10⁻⁹ S/cm).

- Electrons don’t flow easily through the LFP lattice itself. Instead, they “hop” short distances via Fe sites—but this is inefficient.

- To fix this, manufacturers coat the particles with carbon or mix in conductive additives (carbon black, graphene, CNTs).

- Without this, the cathode would behave like an insulator.

⚡ In Simpler Terms

- LFP is safe and stable because of its crystal structure.

- But it’s like a highway with only one lane for lithium ions. If the lane is blocked (by impurities or defects), traffic slows down.

- And while lithium ions can move through that lane, electrons can’t easily travel in the crystal at all—they need external “wiring” in the form of carbon coating.

- That’s why manufacturing precision (particle size, purity, coating) is so critical for LFP. If it’s sloppy, you end up with B-grade.

Conductivity & Carbon Coating

- Electronic conductivity of pure LFP is very poor (~10⁻⁹ to 10⁻⁸ S/cm). Thus nearly all viable LFP cathodes require carbon (or conductive additive) distributed so that electrons can reach current collectors.

- Key issues in coatings:

• Uniformity: coating must cover all particles; if some particle bare spots, they’re dead or high resistance.

• Thickness: too thin → insufficient conduction; too thick → extra weight, maybe blocking Li diffusion or adding parasitic reactions.

• Binder and carbon dispersion: mixing differentiations; agglomeration, poor binder adhesion can cause cracks or flaky coatings.

Electrode Porosity, Density, Slurry, Calendaring

- There’s often a tradeoff: higher porosity → easier electrolyte penetration, better ion access, but lower volumetric energy density and possibly mechanical weakness. Lower porosity / higher density → better in some metrics but more difficult to fill with electrolyte, risk of cracking, stress.

- Slurry viscosity and mixing: ensuring homogenous distribution of active material, conductive carbon, binder. If mixing or drying is uneven, you’ll get gradients in density or connectivity.

- Calendaring (compaction after coating) adjusts electrode thickness, packing density, and mechanical stability. Over-compacting causes internal mechanical stress; under-compacting leads to poor energy density and weak conductive networks.

Cell Formation & Initial Cycling

- Formation is the first several charge/discharge cycles. It helps build the solid–electrolyte interphase (SEI) on the anode, stabilizes electrode interfaces, identifies weak cells, and may “burn in” initial defects.

- In A-Grade production, formation often includes “stress tests”: fast charge/discharge, elevated or low temperature, partial states of charge, perhaps cycling at extremes to weed out cells that degrade quickly under stress.

- Testing of internal resistance, impedance spectroscopy over time (not just day-one), to observe growth of resistance (which often foreshadows capacity loss).

Thermal Management, Safety, and Aging

- Thermal stability is one of LFP’s strong suits, but only if everything else is designed well. Poor coatings or electrolyte, or defects, can lead to local heating, degradation, gas generation, swelling, or worse.

- Aging comes from multiple processes: repeated cycling; chemical side reactions; lithium plating (especially under fast charging or low temperature); electrolyte decomposition; binder decomposition; mechanical stress causing cracking or loss of contact within electrodes.

- In Automotive / A-Grade, there are strict thermal abuse tests, overcharge/overdischarge tests, vibrational / mechanical stress tests, environmental cycling (humidity, temperature), etc.

Case Studies / Numbers (Where Available)

While much of what top battery makers do is proprietary, there are published figures and real-world comparisons that can help illustrate differences:

- Cycle life: Good A-Grade LFP cells are reported to exceed 3,000 to 6,000 full cycles (with high retention) under moderate rate and temperature. Some even more, depending on conditions (depth of discharge, temperature).

- B-Grade cells sometimes only manage 1,500-2,500 cycles under similar conditions before capacity drops significantly.

- Internal resistance spread: in well controlled batches, cell-to-cell variance can be small (e.g. a few milliohms variation). In B-Grade, variance can be much larger, meaning pack balancing becomes harder, and weaker cells dictate pack life.

What This Means for Buyers, Users, Engineers

- If you’re selecting batteries (EV, solar, storage), know what you’re getting: ask for data on cycle life, internal resistance, rate capability, thermal stability.

- Examine the warranty: often A-Grade supply will guarantee performance (e.g., ≥ 80 % capacity after X years or Y cycles). B-Grade might have much more limited or vague warranties.

- For pack designers / systems engineers: ensure BMS / thermal management takes into account worst-case cells (which are often the weak ones). With high cell variance, balancing and module design become more complex.

- For users: operating conditions matter. Fast charging, frequent deep discharges, high/low temperature extremes will exacerbate weaknesses. Even a great A-Grade cell can be abused; B-Grade will degrade faster or misbehave.

Summary

Here’s a compact summary:

- Automotive / A-Grade LFP means: high purity, tight process control, uniform particle size and carbon coating, strong quality control (electrical, mechanical, thermal), test formation, sorting and binning, rigorous safety margins. These cells are built to last, perform under stress, and show low variance across batches.

- B-Grade/Off-Spec LFP are those that don’t pass some of those tests: perhaps good on paper, but weaker in rate, cycle life, or durability. Often cheaper, ok for less demanding applications—but risk of early failure, more degradation, possibly safety or reliability compromises.

Video & Image Resources / Suggestions

To help readers visualize, here are some existing videos/resources + ideas for images or diagrams you could commission or source:

- Videos:

• “Li-ion Battery Chemistries Explained: LFP vs NMC” – gives a broad comparison. YouTube

References

GB/T 31485-2015: PDF in English. (chinesestandard.net)

SHIPPING and Verification of our cells

Our warehouse in China packs our cells into boxes of 2 or 4pcs for easy delivery in Australia. EVE supply our Bulk A grade purchases. This is done for ease of shipping, as per the regulations found here link. UN3480

EVE data is supplied with True A grade product, it’s unmistakable, its supplied in an excel spreadsheet, and contains the QR code, date of manufacturer, location of manufacture and other important information. We will give you a copy of the original EVE data. Usually part of a larger order, sometimes as large as 800pcs.

You can then contact EVE yourself to verify the QR codes should you have a reason to do that.

WE ARE NOT GOING TO PUBLISH THIS DATA ONLINE, BECAUSE OTHER COMPANIES WILL ATTEMPT TO COPY IT

All Lithium batteries are dangerous goods and, as such, require special packaging for transportation.

All domestic and international shipments containing lithium batteries are subject to transport regulations on hazardous goods according to ADR RID, ADN, IMDG, ICAO / IATA Regulations.

The batteries UN3480 are lithium-ion batteries, rechargeable, without equipment.

The lithium-ion batteries UN3480 are classified:

Class 9 – UN3480 – Lithium-ion batteries – Batteries that are not packed with or installed with the equipment.

For each model of battery, there are different requirements to be verified:

– Type of battery.

– Weight of the battery.

– Dimensions of the battery.

– Capacity of the battery.

– Mode of transport.

HERE ARE SOME OF OUR LIFEPO4 AUTOMOTIVE BATTERY

-

Product on sale

12V EVE MB31 314Ah LiFePO4 4.02 kWh Battery Pack Kit with Smart BMS – LIFEPO4 BMS 4sOriginal price was: $1,754.00.$1,250.00Current price is: $1,250.00.

12V EVE MB31 314Ah LiFePO4 4.02 kWh Battery Pack Kit with Smart BMS – LIFEPO4 BMS 4sOriginal price was: $1,754.00.$1,250.00Current price is: $1,250.00. -

EVE 100Ah 3.2v Prismatic LFP cell – PRE ORDER ONLY$160.00

EVE 100Ah 3.2v Prismatic LFP cell – PRE ORDER ONLY$160.00 -

EVE LF22K LFP ULTRA HIGH POWER 3C 4500 CYCLES$100.00

EVE LF22K LFP ULTRA HIGH POWER 3C 4500 CYCLES$100.00 -

Product on sale

EVE MB31 314AH 3.2v LFP Automotive GradeOriginal price was: $399.00.$199.00Current price is: $199.00.

EVE MB31 314AH 3.2v LFP Automotive GradeOriginal price was: $399.00.$199.00Current price is: $199.00. -

Product on sale

EVE MB56 628ah 3.2v LFPOriginal price was: $499.00.$299.00Current price is: $299.00.

EVE MB56 628ah 3.2v LFPOriginal price was: $499.00.$299.00Current price is: $299.00. -

Product on sale

EVE MB30 306AH 3.2v LFP A+ GradeOriginal price was: $399.00.$200.00Current price is: $200.00.

EVE MB30 306AH 3.2v LFP A+ GradeOriginal price was: $399.00.$200.00Current price is: $200.00. -

Product on sale

EVE 304AH LF304 Automotive GradeOriginal price was: $440.00.$250.00Current price is: $250.00.

EVE 304AH LF304 Automotive GradeOriginal price was: $440.00.$250.00Current price is: $250.00.