Why Natron Energy Collapsed

What happens when mass manufacturing and scale disrupts new and sometimes better technology for niche applications

Inside the $1.4B Battery Dream That Died Overnight

Just one year after announcing a $1.4 billion sodium-ion battery gigafactory that promised 1,000 high-wage jobs in rural North Carolina, Natron Energy is gone.

On September 4, 2025, the 13-year-old California startup shut down all operations, laid off its entire workforce of ~95 employees, and abandoned plans for what was to be one of the largest sodium baed clean-energy investments in the USA

The news hit like a shockwave — not just for the workers in Michigan and California, but for state officials who had already approved $56.3 million in incentives (none of which were paid).

So what went wrong?

In this deep-dive investigation, we uncover the real reasons behind Natron’s collapse — from frozen investor payments and policy shifts to manufacturing economics and a fatal mismatch between innovation and market timing.

The Final Days: A Desperate Search for Cash

According to internal documents and interviews, Natron’s board made the final call on August 27, 2025: fundraising efforts had failed.

“Natron’s efforts to raise sufficient new funding were unsuccessful, having failed to result in sufficient funding proceeds to cover the required additional working capital and operational expenses.”

— Elizabeth Shober, Head of Team & Talent, in letter to Michigan labor officials

The company had been in survival mode for months:

- Existing investors — including Chevron, United Airlines Ventures, and Khosla Ventures — froze scheduled payments starting in June 2025.

- A Series B round was pitched but never closed.

- Debt financing talks collapsed.

- Even a last-ditch asset sale (via California advisory firm Sherwood Partners) came too late.

By late August, Natron had only $25 million USD in booked orders — mostly for data center backup power — but couldn’t fulfill them. Certification delays (UL 1973) and the looming 60-day WARN Act layoff notice created a death spiral:

no delivery → no revenue → no investor confidence → no lifeline.

CEO Colin Wessells stepped down in December 2024 — citing the “all-consuming” burden of fundraising. His departure was an early warning sign.

The Cost Conundrum: BOM vs. Reality

Natron’s sodium-ion batteries were built on a compelling promise: cheaper, safer, more sustainable than lithium-ion.

Using Prussian blue electrodes and abundant materials like sodium, aluminum, iron, and manganese, the company avoided lithium, cobalt, and nickel entirely. No rare earths. No geopolitical risk.

| Component | Natron (Sodium-Ion) | Lithium-Ion (LFP) |

|---|---|---|

| Cathode | Prussian blue (Fe, Mn, Na) | Lithium iron phosphate |

| Anode | Hard carbon | Graphite |

| Electrolyte | Sodium salt in organic solvent | Lithium salt |

| Projected BOM Cost (2030) | $10/kWh (grossly exaggerated) | $40–60/kWh |

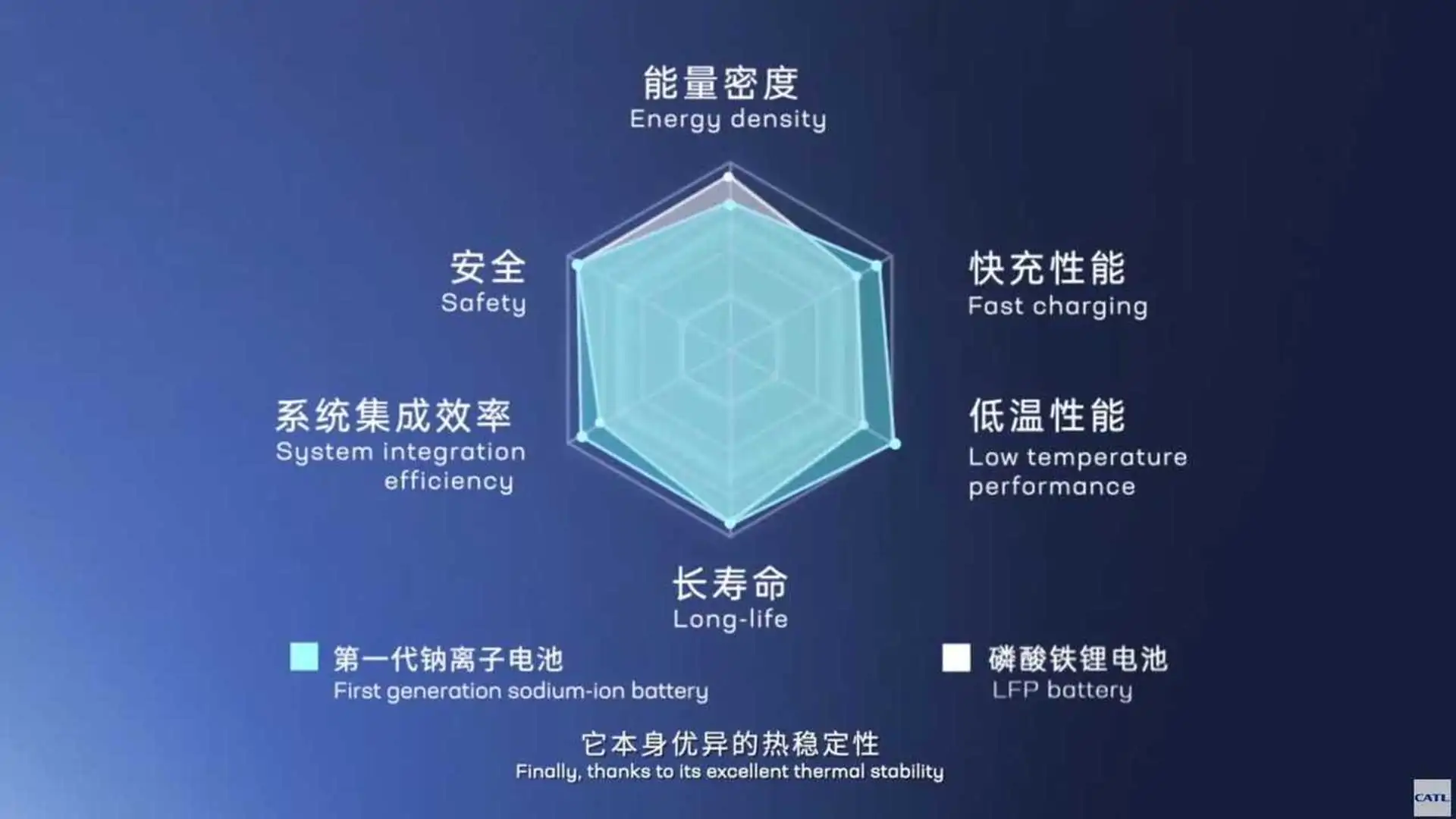

But here’s the catch: low energy density (~50 Wh/L vs. 300 Wh/L for Li-ion) meant Natron’s batteries were only viable for power-dense applications like grid or data centre stabilization and or possibly fast-charging stations — not EVs or consumer devices. The reality was, they were heavy, and huge. And over time, the price of Lithium based batteries fell so quickly, that most technology has been put out of business.

China dominates battery manufacturing, overnight in december 2024, CATL announced a 50% price drop for LFP batteries at the cell level. From around $100 per kWh to $50 per kWh. This price is wholesale, without any retail margins, so its not the true cost, but it gives you an idea, of the power they can weild, this also affected many other chinese companies, such as Gotion, but this decision also completely wiped out all the planned factories across the globe, some in the USA, and some in Australia who had been budgeting for $100 a kWh, they now had no future.

China is not messing around, this is a fight that without mega Billions of dollars, supply chains and the highest level of automation, the competiting countries have no chance of getting off the ground.

And while long-term BOM costs looked promising, scaling manufacturing was brutally expensive:

- Retrofitting the Michigan plant cost $40 million.

- The North Carolina gigafactory was budgeted at $1.4 billion — 40x the Michigan site’s capacity.

- Upfront system costs were higher than Li-ion initially, with savings only over 50,000+ cycles.

Even with $35/kWh IRA tax credits, the math didn’t work without massive volume — and volume required capital Natron no longer had.

Market Timing: The Lithium Price Crash

In 2022, lithium carbonate hit $80,000/ton. Sodium-ion looked like the future.

By 2025? Under $10,000/ton. A 70%+ collapse.

Suddenly, lithium iron phosphate (LFP) batteries — already dominant in China — became cheaper than ever. Data centers and utilities asked: Why switch to an unproven chemistry?

Natron’s niche advantage evaporated.

The Full Breakdown: Why Natron Failed

| Factor | Impact | Outcome |

|---|---|---|

| Frozen Investor Payments | Chevron, United, Khosla halted funds in June 2025 | Cash runway ended |

| Policy Shift | Reduced federal support under Trump admin; ARPA-E grants stalled | Lost goodwill funding |

| Certification Delays | UL 1973 blocked $25M in orders | No revenue to show investors |

| Lithium Price Crash | 70% drop eroded cost edge | Customers stayed with LFP |

| High CapEx for Low-Density Tech | $1.4B factory for power-focused batteries | Too risky without scale |

| China Dominance | ~100% of global sodium-ion capacity | U.S. startups outgunned |

What’s Next for Sodium-Ion?

Natron’s collapse is not the end of sodium-ion technology.

Experts like those at Mana Battery call it “very specific to Natron” — citing execution missteps, niche focus, and bad timing. Others, like Bedrock Materials and Peak Energy, are still advancing sodium-ion with smaller, grid-focused strategies.

China already has over 10 GWh of sodium-ion capacity online. The chemistry works. The market exists.

But Natron’s story is a sobering reminder: in clean energy, innovation alone isn’t enough. You need capital, timing, policy, and customers — all aligned.

North Carolina’s Kingsboro megasite is back on the market.

State officials call it “one of the top megasites in the country.”

This was its second major flop in seven years.

Sources & Further Reading

- WRAL News – Original closure announcement

- Battery industry reports (2024–2025): Mana Battery, BloombergNEF, ARPA-E

- Internal Natron documents via Michigan WARN Act filings

- Interviews with former employees and industry analysts