Description

JKBMS Relay BMS Split Port BMS + 2 x 500A Relays

Included components

1 x JKBMS Relay BMS Split Port BMS for 24v, 36v, 48v, 60v, 72v and 80v Battery packs

2 x TE Connectivity EVC 500 Main Contactors (TE Connectivity AMP+ EVC 500, Mfr. Part No. 2299223-1 or equivalent)

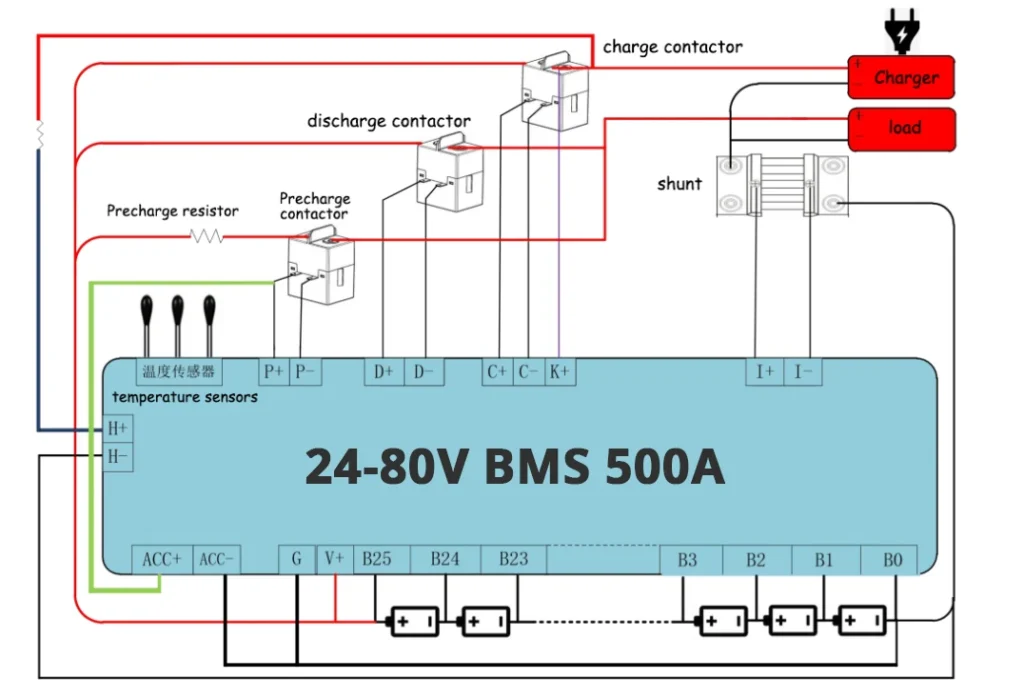

External 500 A, 12 V-coil relays driven by the BMS’s CHG+ and DCH+ wires—one to interrupt charging and one to interrupt discharging for full fault isolation

1 x 100A EV4010A Relay for PreCharge resistor

1 x 48-12v DC Converter (48V-72V to 13.8V 20A 240W DC DC Step Down Converter Voltage Regulator)

Key Specifications

Battery String Configuration: 7- to 25-series (7S–25S)

Continuous Current Rating: 500 A (via 2 x external relay, (1 charge/1 x discharge)

Power Supply Mode: Self-powered by battery pack

Single-Cell Voltage Monitoring: 0–5 V range; maximum error < 10 mV (typical < 5 mV)

Cell Dropout Detection: Yes

Active Balancing Current: 2A (full-state on)

Wiring Configuration: Common-port connection

Short-Circuit Protection: Yes

Communications & Monitoring

Bluetooth Connectivity: Built-in; compatible with Android and iOS devices

Temperature Sensing: –40 °C to 125 °C

System-Level Measurements

Total Voltage Detection: 0–100 V; accuracy within 0.5 % of full scale

Current Sensing (Shunt): –150 A to 300 A; accuracy within 0.5 % of full scale

State-of-Charge (SoC) Estimation: ± 8 % error under typical operating conditions

Remaining Capacity Display: Error ± 8 %

Cumulative Ampere-Hour Counter: Tracks half of total charge/discharge value

Power Consumption

Active Operating Current: < 5 mA (idle); 15 mA (with RS-485 or CAN communication)

Standby Current: < 2 mA

Environmental Ratings

Operating Temperature: –40 °C to 85 °C

Storage Temperature: –40 °C to 95 °C

Installation Guide: Forklift BMS 500A

Please follow these steps carefully to ensure a safe and reliable installation of your Forklift BMS 500A.

Installation Instructions

1. Unpack and Inspect

Open the package and visually inspect the BMS module and current shunt for any damage.

Observe basic anti-static precautions: handle the electronics by their edges and avoid touching exposed circuitry.

2. Mount the BMS Module

Select a clean, dry location inside your battery enclosure.

Secure the BMS by its mounting holes on an insulated, vibration-resistant surface.

3. Install the Current Shunt

Place the shunt adjacent to the pack’s negative busbar.

Tighten the M8 power terminals to the manufacturer’s torque specification for accurate current sensing.

4. Wire the Cell-String Leads

Connect each cell-string lead in sequence (from B– up through B1, B2… to B+), matching the markings on the BMS.

Double-check polarity and order with a multimeter before moving on.

5. Attach Temperature Sensors

Plug in up to three temperature probes into the BMS sensor ports.

Secure the probes to representative cells or busbars to monitor pack temperature.

6. Connect Charge and Discharge Outputs

Wire the “C+” and “C–” terminals to the charge contactor coil.

Wire the “D+” and “D–” terminals to the discharge contactor coil.

Tie both coil-negative lines to the pack’s negative (ground).

7. Power the BMS Electronics

Apply your pack voltage (40–60 V) to the BMS power input terminals.

Ensure any accessory or ignition-sense inputs are wired as required for your application.

8. Initial Power-Up and Inspection

With all wiring secured, switch on pack power.

Confirm the BMS powers up (power LED on) and shows no active fault indicators.

9. Pair with the Mobile App

Download the BMS app on Android or iOS.

JK BMS App Android Apple iOSEnable Bluetooth on your phone, open the app, and connect to the BMS (default password 1234).

Configure cell count, pack capacity, and protection thresholds using the app’s guided setup.

10. Calibrate and Test

In the app, calibrate voltage and current readings against your pack’s terminals.

Perform a controlled test of both charge and discharge outputs and verify cell balancing functionality before full-load operation.

Key Considerations:

Always follow torque specs on all terminals.

Ensure a reliable 12 V supply for your contactor coils (via DC–DC converter or auxiliary battery).

Verify proper function in a safe test environment before returning the forklift to service.

This installation procedure ensures optimal performance, safety, and longevity for your 51.2 V LiFePO₄ forklift battery system.